Nchịkọta oru ngo

1. Mmemme Mmepụta

600 set / ụbọchị (117/118 nwere pedestral)

2. Ihe achọrọ maka ahịrị nhazi:

1) NC machining center dabara adaba maka ahịrị mmepụta akpaaka;

2) Hydraulic frock mmachi;

3) Ngwunye akpaaka na ngwaọrụ oghere na ngwaọrụ ebufe;

4) N'ozuzu teknụzụ nhazi na nhazi oge okirikiri;

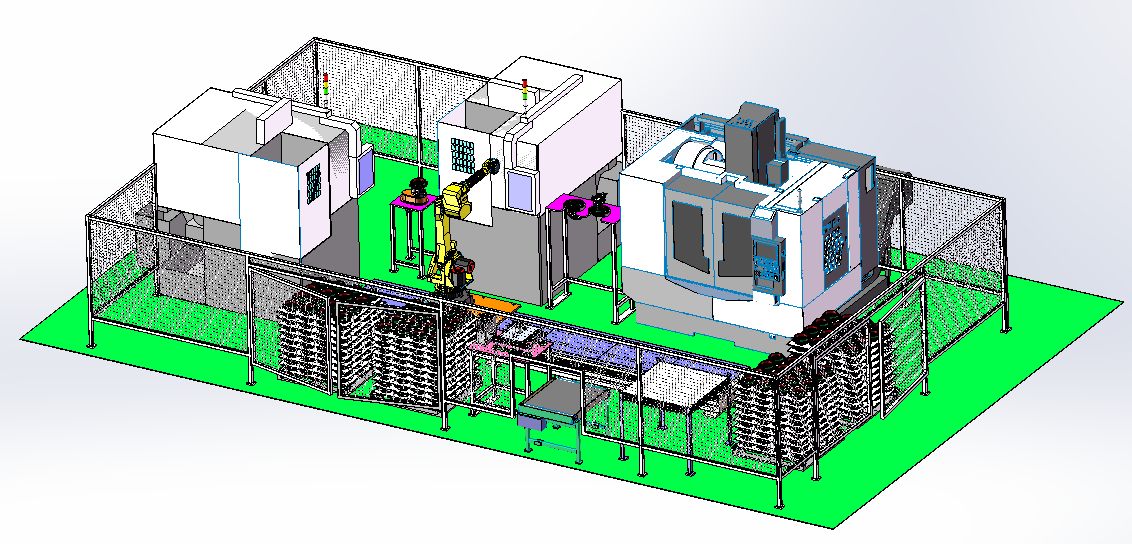

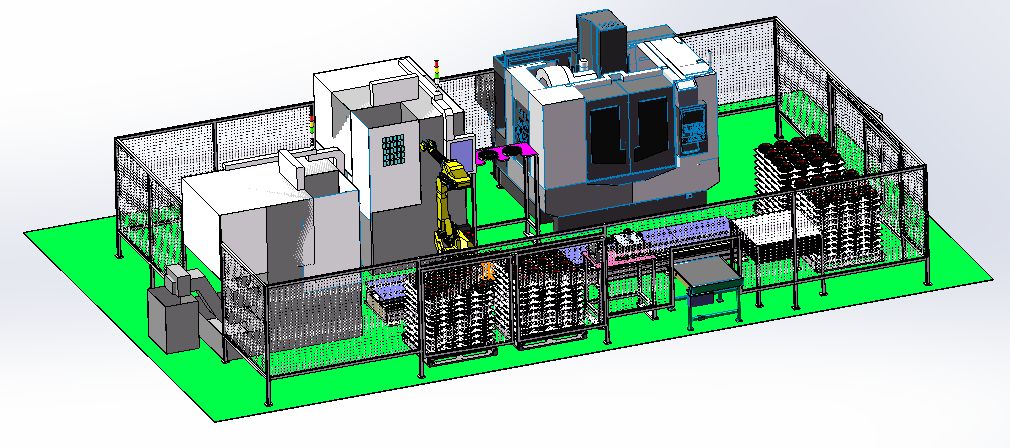

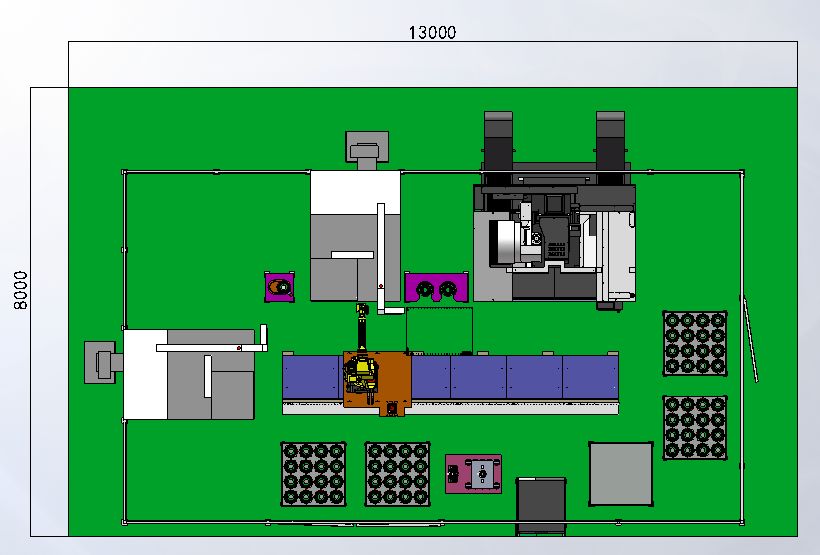

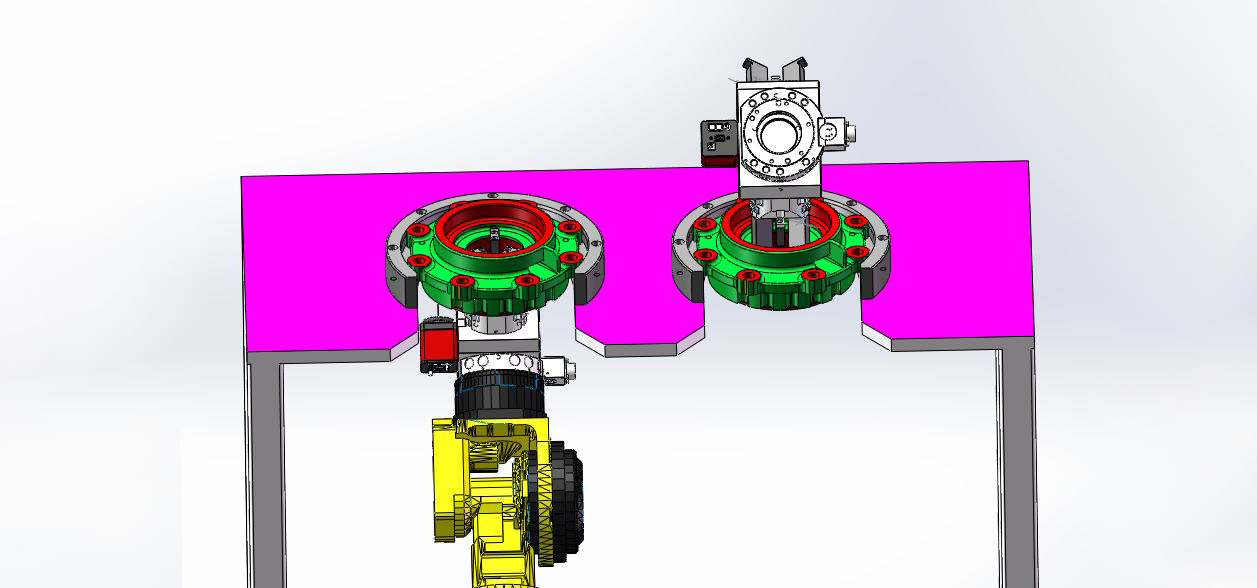

Nhazi nke ahịrị mmepụta

Nhazi nke ahịrị mmepụta

Mmalite nke Omume Robot:

1. Jiri aka tinye ihe ndị a na-arụ ọrụ nke ọma ma tinye nkata n'elu tebụl na-ebu ibu (N'elu tebụl nke nọmba 1 na nke 2) wee pịa bọtịnụ iji gosi;

2. The robot na-akwaga na tray nke No. 1 loading table, meghere usoro ọhụụ, jidere ma na-akpali akụkụ A na B n'otu n'otu na angular ikiri ọdụ na-echere loading ntụziaka;

3. A na-ezipụ ntụziaka nbudata site n'ọdụ njirimara angular. The Robot na-etinye Mba 1 ibe n'ime n'ọnọdu ebe nke turntable. Tụgharịa na turntable na-amalite angular ude usoro, chọpụta angular ọnọdụ, kwụsị turntable na mechaa angular ude nke Nke 1 ibe;

4. Usoro njirimara angular na-eziga iwu na-adịghị ọcha, na robot na-ebuli ihe nke 1 ma tinye nọmba 2 maka njirimara. The turntable na-atụgharị na usoro njirimara angular na-amalite iji chọpụta ọnọdụ angular. The turntable akwụsị na angular ude nke Nke 2 ibe na-agwụ agwụ, na blanking iwu ezipụ;

5. The Robot na-enweta iwu na-adịghị ọcha nke No. 1 vetikal lathe, na-akpali na loading na blanking ọnọdụ nke No. 1 vetikal lathe maka ihe blanking na loading. Mgbe emechara ihe omume ahụ, otu akụkụ machining okirikiri nke vetikal lathe na-amalite;

6. The robot na-ewe okokụre ngwaahịa site No. 1 vetikal lathe na-etinye ya na No. 1 ọnọdụ na workpiece mpịakọta-n'elu table;

7. The robot na-enweta na blanking iwu nke No. 2 vetikal lathe, na-akpali na loading na blanking ọnọdụ nke 2 vetikal lathe maka ihe blanking na loading., na mgbe ahụ omume na-agwụ agwụ, na otu-ibe nhazi okirikiri nke vetikal lathe amalite;

8. The robot na-ewe okokụre ngwaahịa site No. 2 vetikal lathe na-etinye ya na Nke 2 ọnọdụ na workpiece mpịakọta-n'elu table;

9. Robot na-echere iwu efu site na igwe kwụ ọtọ;

10. The vetikal machining na-eziga ndị blanking iwu, na robot na-akpali na loading na blanking ọnọdụ nke vetikal machining, grabs na-akpali ndị workpieces nke No. The robot na-akpali na mpịakọta-n'elu table ịghọta na-ezipụ Mba 1 na Mba 2 iberibe na vetikal machining loading na blanking ọnọdụ karị, na ebe Nke 1 na Nke 2 workpieces n'ime n'ọnọdu n'ógbè nke 1 na Mba 2 ọdụ nke hydraulic mwekota karị iji mezue vetikal machining loading. Robot na-esi na ebe nchekwa dị anya nke igwe kwụ ọtọ wee malite otu usoro nhazi;

11. The robot na-akpali na No. 1 loading tray na-akwadebe maka mmalite nke sekọndrị okirikiri mmemme;

Nkọwa:

1. The Robot na-ewere 16 iberibe (otu oyi akwa) na loading tree. Robot ahụ ga-edochi tong iko mmiri ara ma tinye efere nkebi na nkata nchekwa nwa oge;

2. Robot na-akwakọba iberibe iri na isii (otu oyi akwa) na tray na-adịghị ọcha. The robot kwesịrị dochie suction cup tong otu ugboro, na-etinye nkebi efere n'elu nkebi elu nke akụkụ si nwa oge nchekwa nkata;

3. Dị ka ugboro nyocha, jide n'aka na robot na-etinye akụkụ na tebụl nlele akwụkwọ ntuziaka;

| 1 | Usoro okirikiri machining | ||||||||||||||

| 2 | Onye ahịa | Ihe eji arụ ọrụ | QT450-10-GB/T1348 | Ihe nlere nke igwe igwe | Ebe nchekwa nọmba. | ||||||||||

| 3 | Aha ngwaahịa | 117 oche oche | Ihe osise Mba. | DZ90129320117 | Ụbọchị nkwadebe | 2020.01.04 | Mepụtara site na | ||||||||

| 4 | Usoro usoro | Mma No. | ọdịnaya igwe | Aha akụrụngwa | Ịcha dayameta | Ịcha ọsọ | Ọsọ ntụgharị | Nri kwa mgbanwe | Ngwa igwe na-enye nri | Ọnụ ọgụgụ nke cuttings | Usoro ọ bụla | Oge nhazi | Oge efu | Oge ntụgharị axis anọ | Oge mgbanwe ngwá ọrụ |

| 5 | Mba. | Mba. | Desoriptions | Ngwa | D mm | n | R pm | mm/Mkpu | mm/Nkeji | Oge | mm | Nkeji | Nkeji | Nkeji | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Egwu arịọnụ oghere elu | Dayameta nke onye na-egwe ọka 40 ihu | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | |

| 8 | Gwuo DIA 17 oghere mgbago | DIA 17 ejikọtara egwu egwu | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||

| 9 | T03 | DIA 17 oghere azụ chamfering | Reverse chamfer cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | ||

| 10 | Nkọwa: | Oge igbu oge: | 62 | Nke abụọ | Oge iji jigide ihe nrụnye yana maka nbudata na ihe efu: | 30.00 | Nke abụọ | ||||||||

| 11 | Oge inyeaka: | 44 | Nke abụọ | Ngụkọta oge ọrụ igwe: | 136.27 | Nke abụọ | |||||||||

| 1 | Usoro okirikiri machining | |||||||||||||||||

| 2 | Onye ahịa | Ihe eji arụ ọrụ | QT450-10-GB/T1348 | Ihe nlere nke igwe igwe | Ebe nchekwa nọmba. | |||||||||||||

| 3 | Aha ngwaahịa | 118 oche oche | Ihe osise Mba. | DZ90129320118 | Ụbọchị nkwadebe | 2020.01.04 | Mepụtara site na | |||||||||||

| 4 | Usoro usoro | Mma No. | ọdịnaya igwe | Aha akụrụngwa | Ịcha dayameta | Ịcha ọsọ | Ọsọ ntụgharị | Nri kwa mgbanwe | nri site igwe ngwá ọrụ | Ọnụ ọgụgụ nke cuttings | Usoro ọ bụla | Oge nhazi | Oge efu | Oge ntụgharị axis anọ | Oge mgbanwe ngwá ọrụ | |||

| 5 | Mba. | Mba. | Desoriptions | Ngwa | D mm | n | R pm | mm/Mkpu | mm/Nkeji | Oge | mm | Nkeji | Nkeji | Nkeji | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Egwu arịọnụ oghere elu | Dayameta nke onye na-egwe ọka 40 ihu | 40.00 | 180 | 1433 | 1.00 | 1433 | 8 | 40.0 | 13.40 | 8 | 4 | ||||

| 8 | T02 | Gwuo DIA 17 oghere mgbago | DIA 17 ejikọtara egwu egwu | 17.00 | 100 | 1873 | 0.25 | 468 | 8 | 32.0 | 32.80 | 8 | 4 | |||||

| 9 | T03 | DIA 17 oghere azụ chamfering | Reverse chamfer cutter | 16.00 | 150 | 2986 | 0.30 | 896 | 8 | 30.0 | 16.08 | 16 | 4 | |||||

| 10 | Nkọwa: | Oge igbu oge: | 62 | Nke abụọ | Oge iji jigide ihe nrụnye yana maka nbudata na ihe efu: | 30.00 | Nke abụọ | |||||||||||

| 11 | Oge inyeaka: | 44 | Nke abụọ | Ngụkọta oge ọrụ igwe: | 136.27 | Nke abụọ | ||||||||||||

| 12 | ||||||||||||||||||

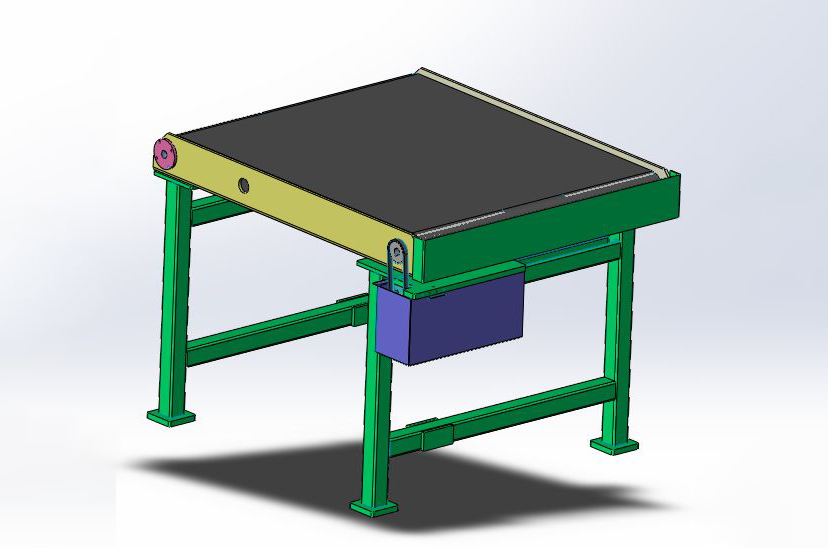

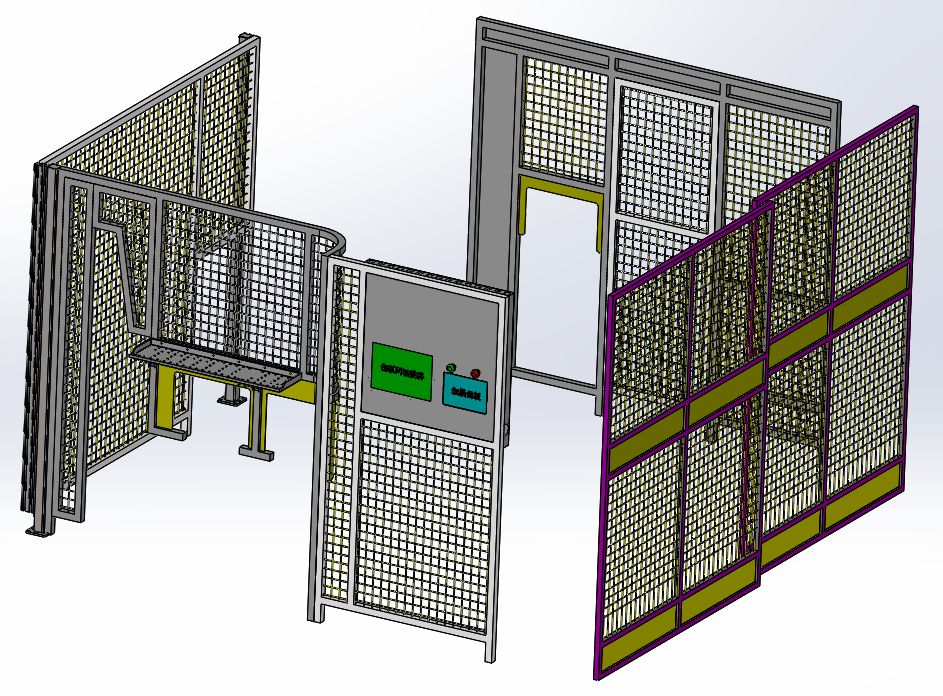

Mpaghara mkpuchi nke ahịrị mmepụta

Okwu mmalite nke isi ọrụ akụrụngwa nke mmepụta akara

Okwu mmalite nke loading na blanking usoro

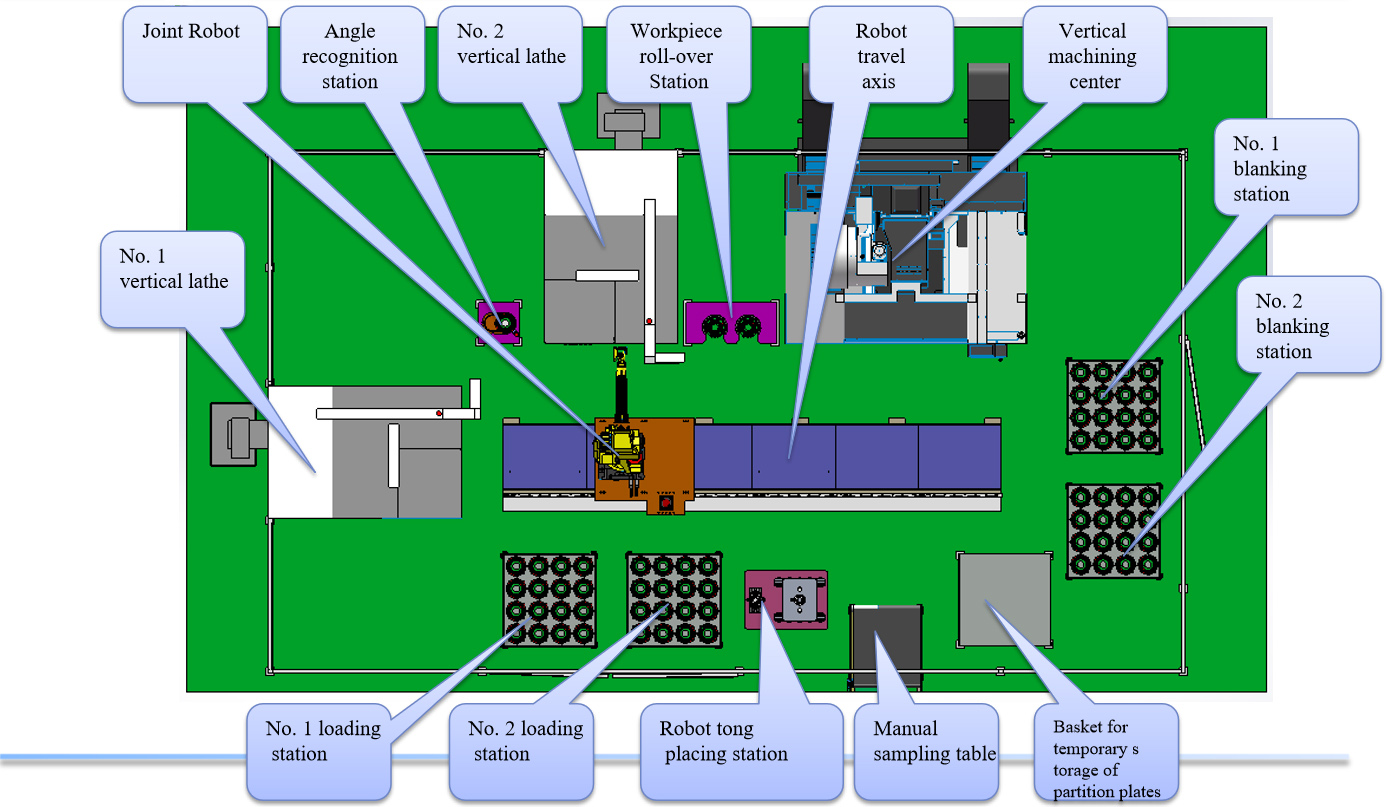

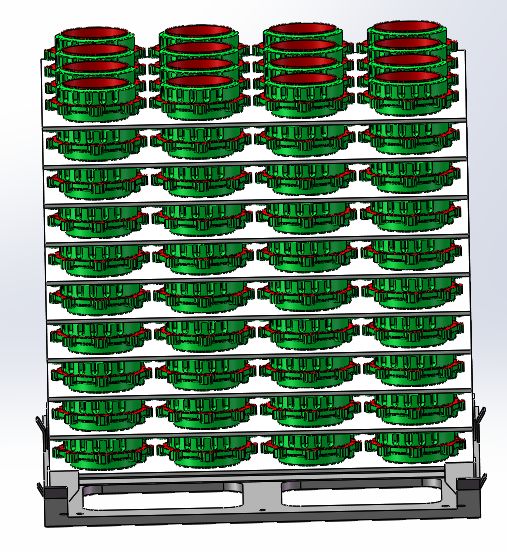

Ihe nchekwa akụrụngwa maka akpaaka mmepụta ahịrị na atụmatụ a bụ: The stacked tray (ọnụọgụ nke iberibe ga-juru n'ọnụ na onye ọ bụla tree ga-negotiated na ndị ahịa), na n'ọnọdu nke workpiece na tray ga-ekpebi mgbe inye 3D ịbịaru nke workpiece oghere ma ọ bụ n'ezie ihe.

1. Ndị ọrụ na-akwakọba akụkụ ndị a na-arụ ọrụ nke ọma na tray ihe (dị ka e gosiri na ọnụ ọgụgụ) ma bufee ha n'ọnọdụ a kara aka;

2. Mgbe dochie tray nke forklift, jiri aka pịa bọtịnụ iji gosi;

3. The robot na-ejide workpiece na-arụ ọrụ loading;

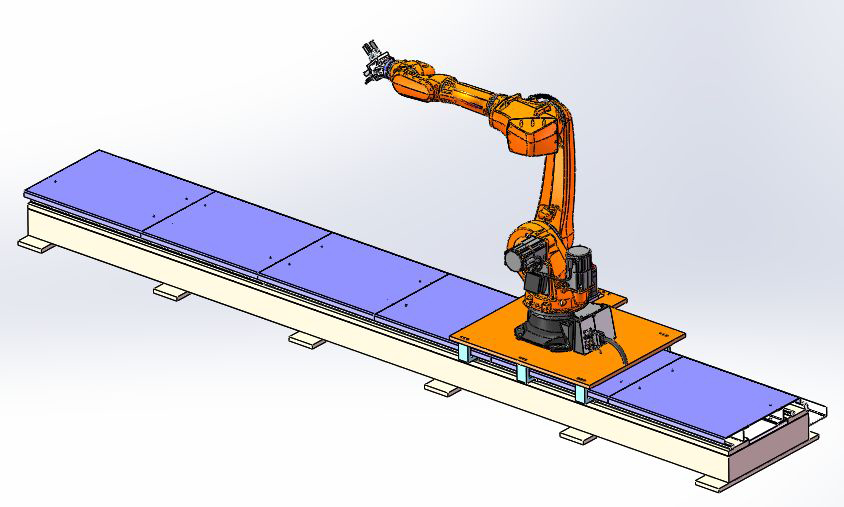

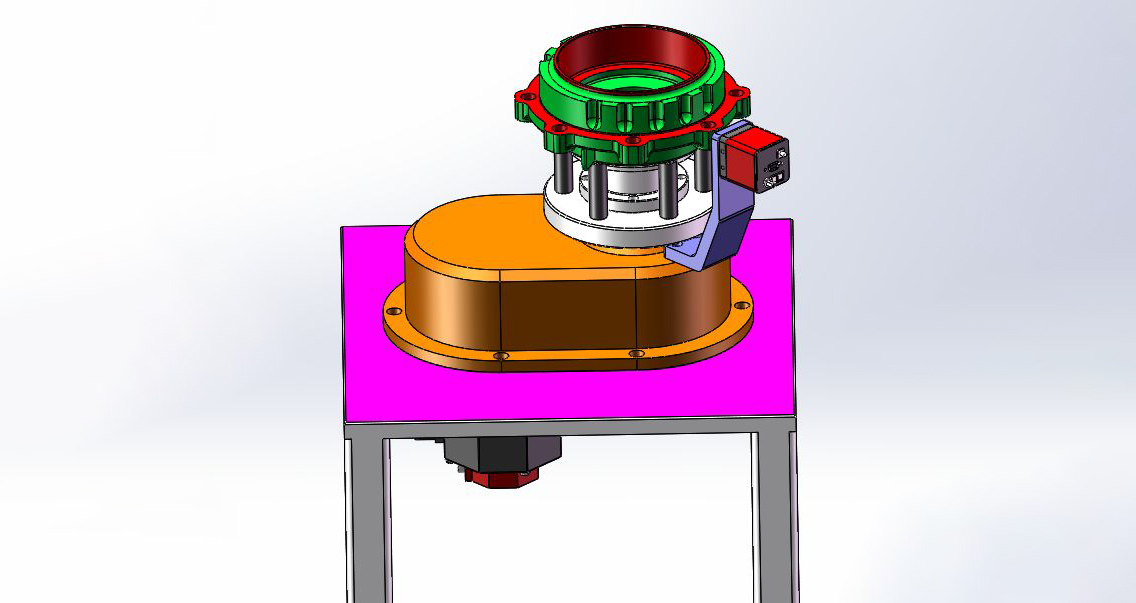

Okwu Mmalite nke Robot Njem Axis

Ihe mejupụtara ya bụ robot nkwonkwo, servo moto mbanye na pinion na rack drive, nke mere na robọt ahụ nwere ike ịmegharị mmegharị azụ azụ na azụ. Ọ na-aghọta ọrụ nke otu robot na-eje ozi ọtụtụ igwe ngwaọrụ na gripping workpieces n'ọtụtụ ọdụ na nwere ike dịkwuo na-arụ ọrụ mkpuchi nke nkwonkwo robots;

Njem egwu na-emetụta ntọala welded na ọkpọkọ nchara ma na-ebugharị ya site na servo moto, pinion na rack drive, na-abawanye mkpuchi na-arụ ọrụ nke robot nkwonkwo ma na-emeziwanye ọnụọgụ nke robot; A na-etinye egwu njem na ala;

Robot Chenxuan: SDCX-RB500

| Data ndabere | |

| Ụdị | SDCX-RB500 |

| Ọnụọgụ anyụike | 6 |

| Mkpuchi kacha | 2101 mm |

| Nwee ike ikwughachi (ISO 9283) | ± 0.05mm |

| Ibu | 553kg |

| Nhazi nchedo nke robot | Ogo nchekwa, IP65 / IP67nkwojiaka n'ahịrị(IEC 60529) |

| Nkwanye ọnọdụ | N'uko ụlọ, ikike n'akuku echiche ≤ 0º |

| Imecha elu, ihe osise | Okpokoro ntọala: ojii (RAL 9005) |

| Ọnọdụ okpomọkụ | |

| Ọrụ | 283K ruo 328K (0 °C ruo +55 Celsius) |

| Nchekwa na njem | 233 K ruo 333 K (-40 Celsius C ruo +60 Celsius) |

Site na ngalaba ngagharị dị iche iche na azụ na ala nke robot, ịbụ ihe nlereanya enwere ike ịwụnye ya na ebuli elu ụlọ. N'ihi na obosara akụkụ nke rọbọt na-ebelata ruo oke, enwere ike itinye ya nso na robot, mkpọgide, ma ọ bụ workpiece dị n'akụkụ. Ntugharị ọsọ dị elu site na ọnọdụ nọrọ na njikere gaa n'ọnọdụ ọrụ na ntinye ngwa ngwa n'oge mmegharị dị mkpirikpi.

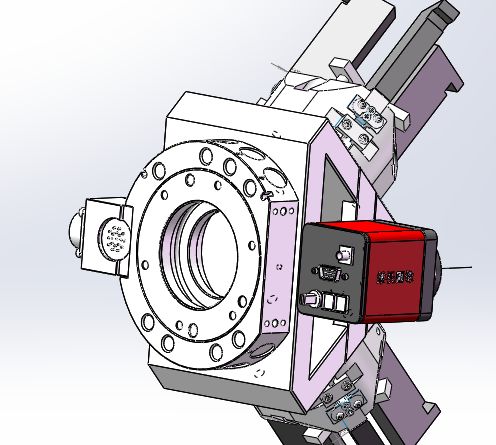

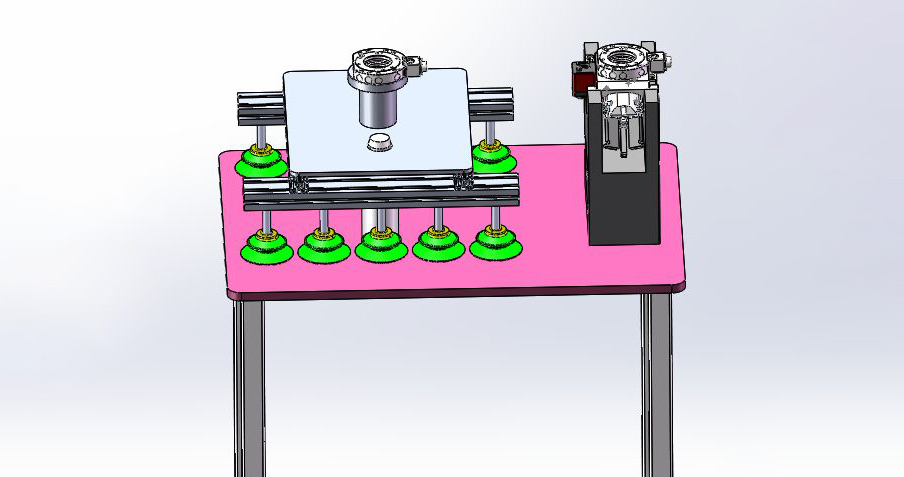

Ngwunye robot nwere ọgụgụ isi na sistemu tong blanking

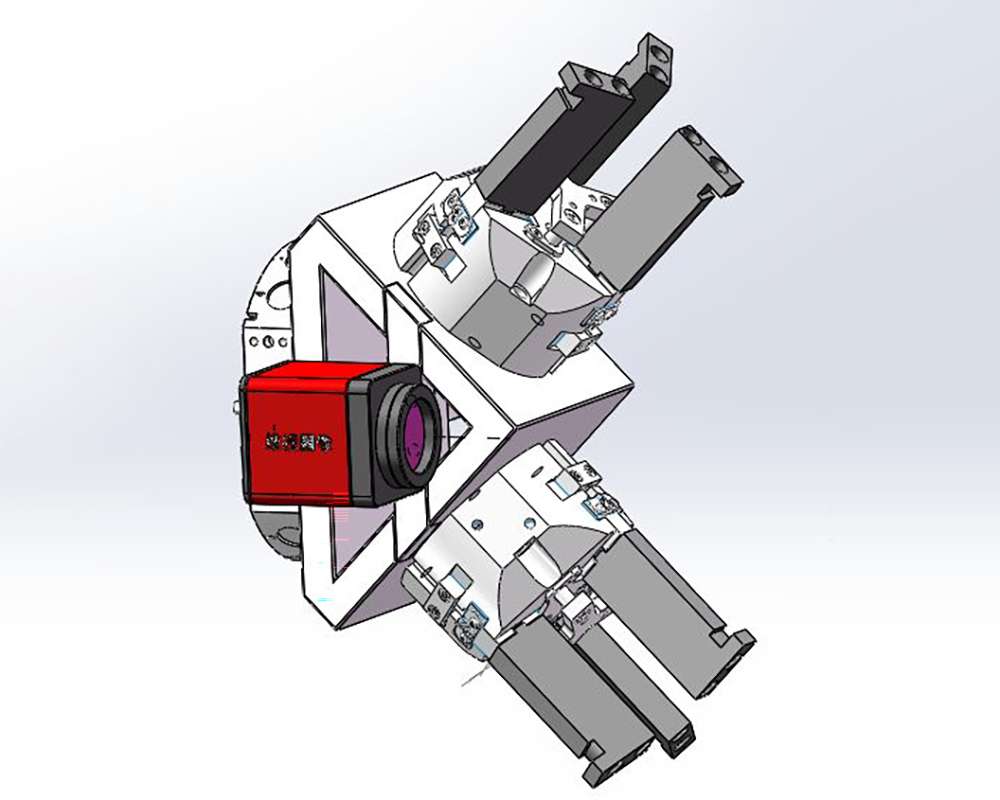

Robot nkebi efere tong usoro

Nkọwa:

1. N'iburu n'uche njirimara nke akụkụ a, anyị na-eji usoro nkwado mpụga nke atọ-claw na-ebu ma wepụ ihe ndị ahụ, nke nwere ike ịghọta ngwa ngwa ntụgharị nke akụkụ na ngwá ọrụ igwe;

2. A na-eji usoro nchọpụta ọnọdụ ọnọdụ na ihe mmetụta nrụgide chọpụta ma ọnọdụ njigide na nrụgide nke akụkụ bụ ihe nkịtị;

3. The usoro na-onwem na a pressurizer, na workpiece agaghị ada apụ na a obere oge na ikpe nke ike ọdịda na gas ebipụ nke isi ikuku sekit;

4. A na-anabata ngwaọrụ na-agbanwe aka. Ịgbanwe usoro ụda nwere ike mechaa ngwa ngwa nkedo nke ihe dị iche iche.

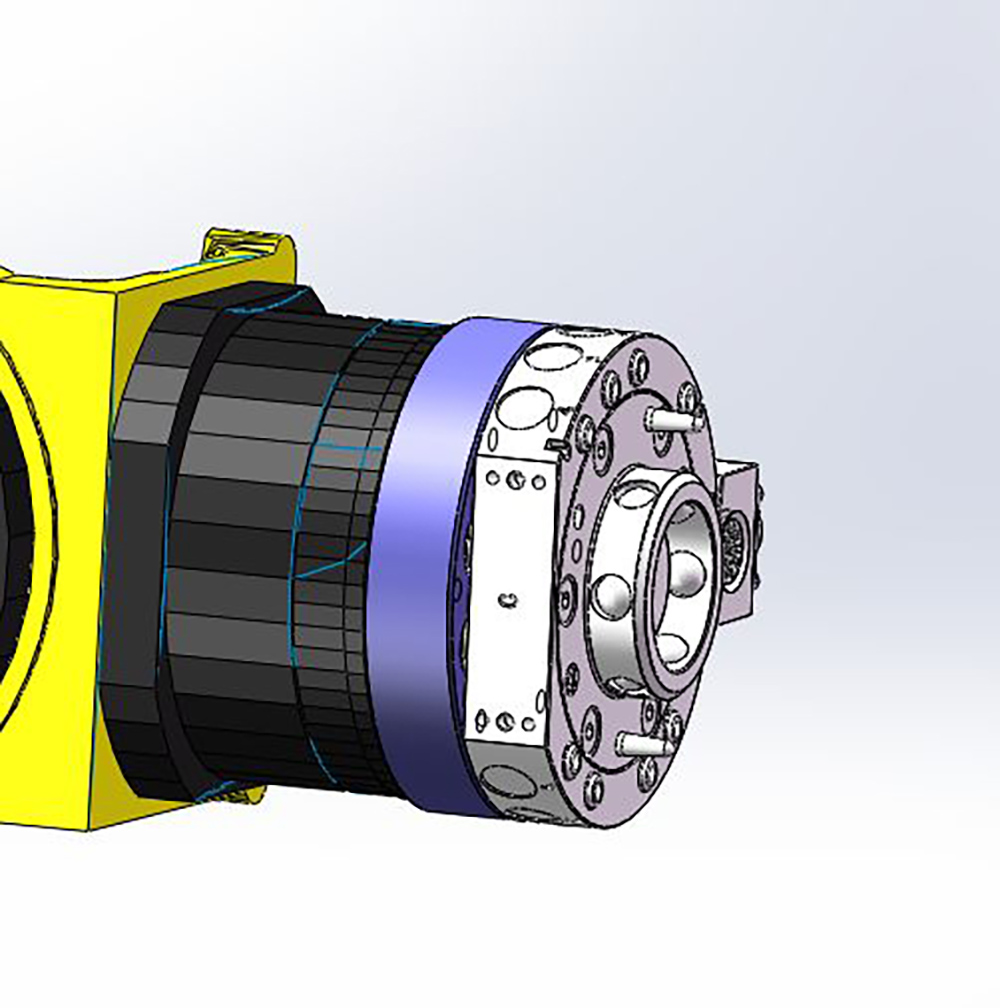

Okwu mmalite nke Tong na-agbanwe ngwaọrụ

A na-eji ngwaọrụ na-agbanwe ụda ụda nke ọma na-agbanwe ngwa ngwa rọbọt, ngwụcha ngwaọrụ na ihe ndị ọzọ na-eme ihe. Belata oge mmepụta ihe na-abaghị uru ma welie mgbanwe nke rọbọt, dị ka:

1. Kpọghe ma mee ka nrụgide ikuku sie ike;

2. Enwere ike iji modul ike dị iche iche, mmiri mmiri na gas;

3. Nhazi ọkọlọtọ nwere ike jikọọ ngwa ngwa na isi iyi ikuku;

4. Ụlọ ọrụ mkpuchi pụrụ iche nwere ike igbochi ihe ize ndụ nke nkwụsị gas na mberede;

5. Ọ dịghị mmiri mmeghachi omume ike; 6. Ọdabara na mpaghara akpaaka;

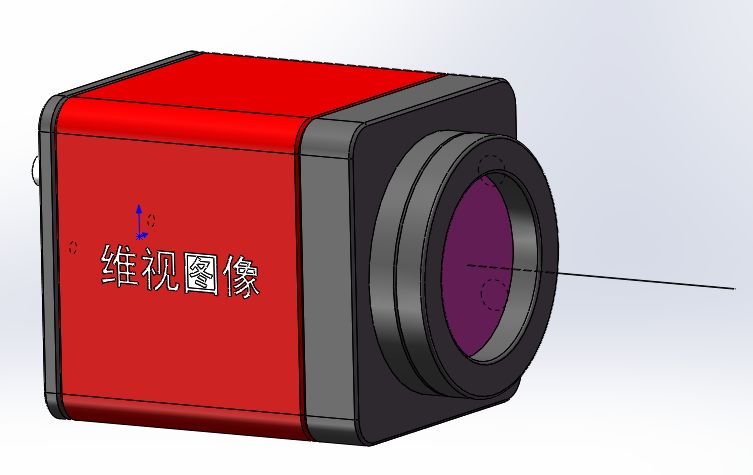

Okwu Mmalite na Ọhụụ Sistemu-Ụlọ ọrụ mmepụta ihe

1. Igwefoto na-anabata CCD na ibe CMDS dị elu, nke nwere njirimara nke oke mkpebi dị elu, ịdị elu dị elu, oke mgbaàmà na-emegharị ugboro ugboro, oke ike dị ukwuu, àgwà foto dị mma na ikike mweghachi agba nke mbụ;

2. Mpaghara n'usoro igwefoto nwere abụọ data nnyefe ụdịdị: GIGAbit Ethernet (GigE) interface na USB3.0 interface;

3. Igwefoto nwere nhazi kọmpat, obere ọdịdị, dị arọ ma tinye ya. Ọsọ mgbasa ozi dị elu, ikike mgbochi mgbochi siri ike, nrụpụta kwụsiri ike nke onyonyo dị elu; Ọ na-adabara maka ịgụ koodu, nchọpụta ntụpọ, DCR na njirimara ụkpụrụ; Igwefoto agba nwere ikike mweghachi agba siri ike, dabara adaba maka ọnọdụ nwere mkpa njirimara agba dị elu;

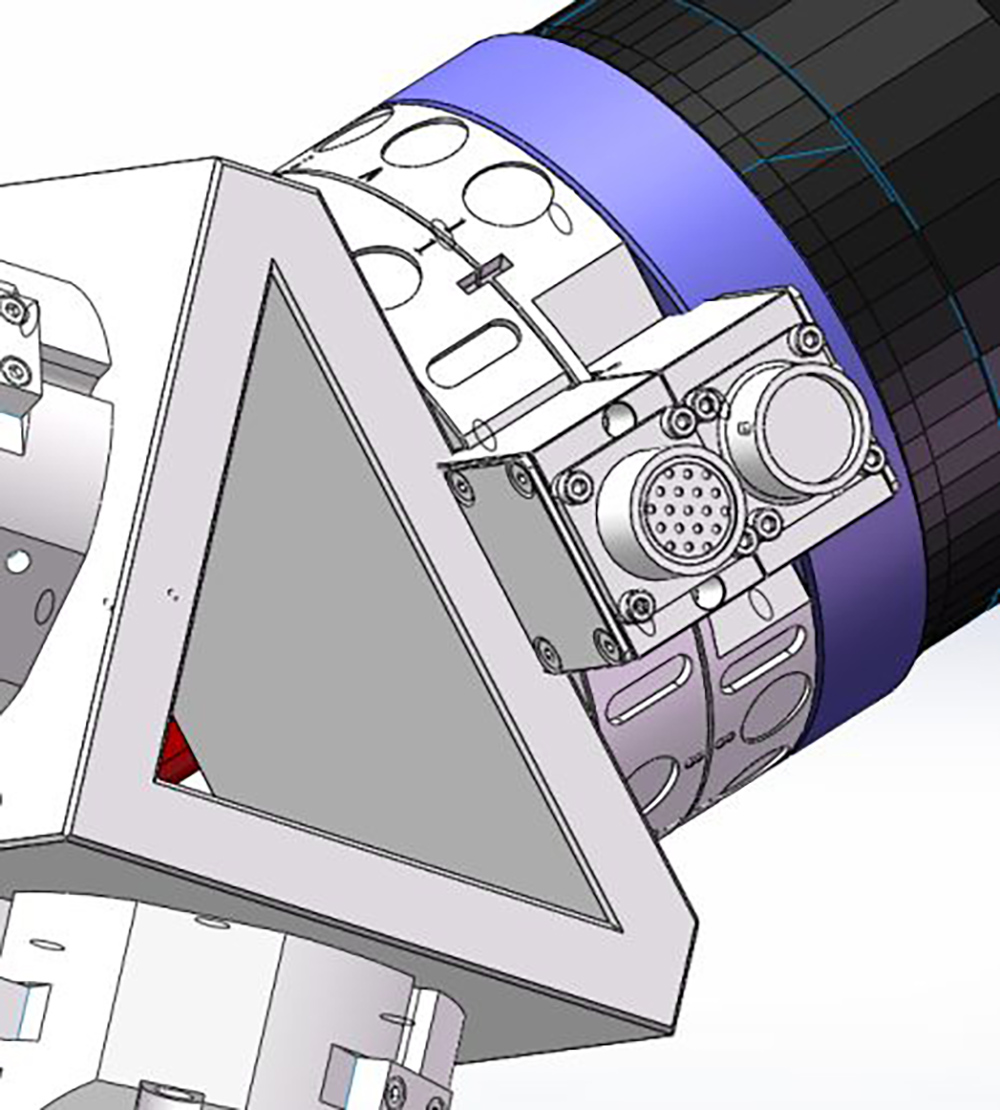

Okwu Mmalite nke Angular Automatic Recognition System

Okwu Mmalite ọrụ

1. The robot clamps workpieces si loading nkata na-eziga ha na n'ọnọdu ebe nke turntable;

2. Turntable na-atụgharị n'okpuru ụgbọala nke servo moto;

3. Usoro a na-ahụ anya (igwefoto ụlọ ọrụ) na-arụ ọrụ iji chọpụta ọnọdụ angular, na ntụgharị ntụgharị na-akwụsị iji chọpụta ọnọdụ angular chọrọ;

4. The Robot na-ewepụta workpiece na-etinye ọzọ ibe n'ihi na angular njirimara;

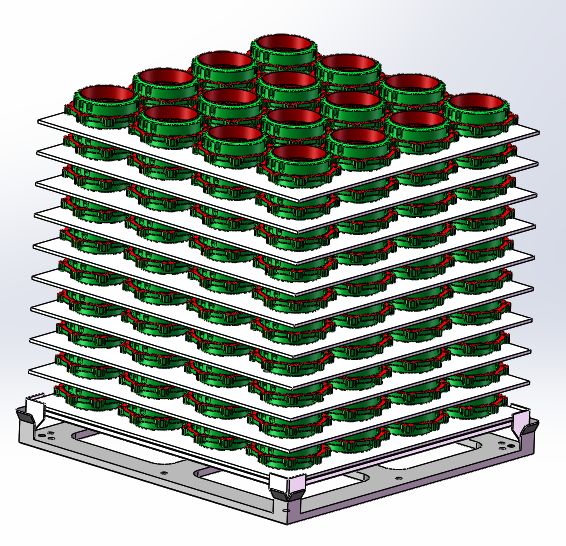

Okwu Mmalite na Workpiece Roll-over Tebụl

Ụlọ ọrụ mbugharị:

1. The robot na-ewe workpiece na-etinye ya na n'ọnọdu ebe na mpịakọta-n'elu table (ekpe ekpe na ọnụ ọgụgụ);

2. The robot aghọta workpiece si n'elu ịghọta rollover nke workpiece;

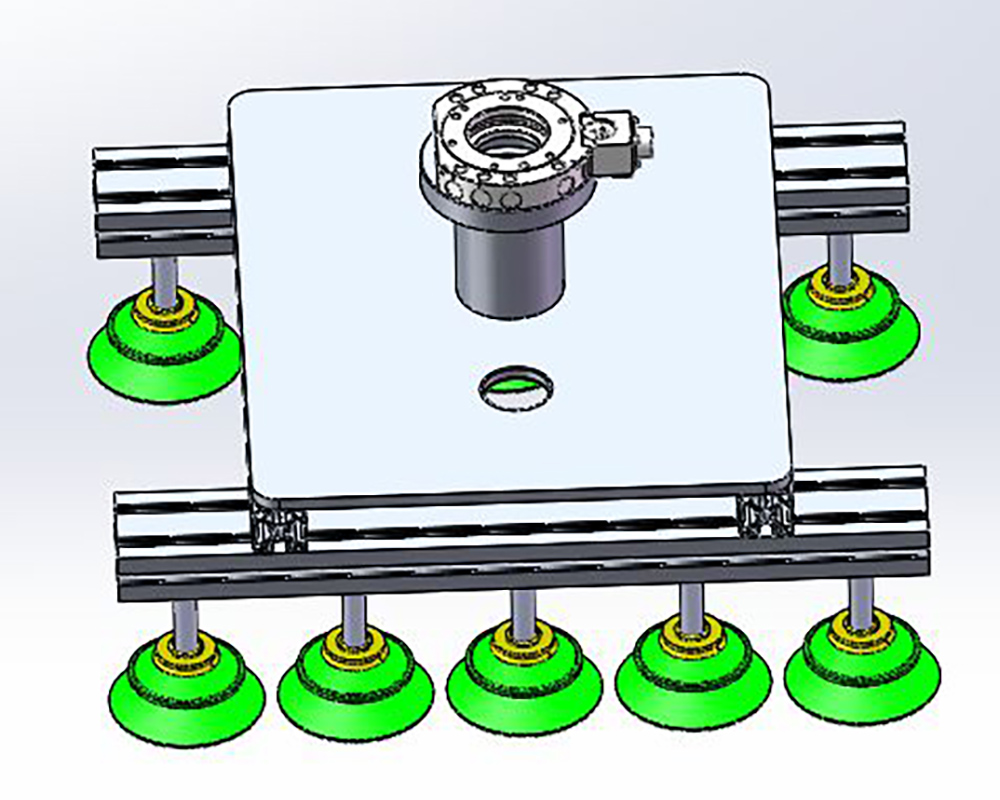

Tebụl na-etinye tong robot

Okwu Mmalite ọrụ

1. Mgbe a na-ebufe akụkụ nke ọ bụla, a ga-etinye efere nkebi nke oyi akwa na nkata nchekwa nwa oge maka efere nkewa;

2. Enwere ike dochie robot ngwa ngwa na mkpịsị iko iko site na ngwaọrụ na-agbanwe agbanwe ma wepụ efere nkebi;

3. Mgbe a na-etinye efere nkebi nke ọma, wepụ iko iko ahụ ma dochie ya na pneumatic tong iji nọgide na-ebufe na ihe ndị na-adịghị ọcha;

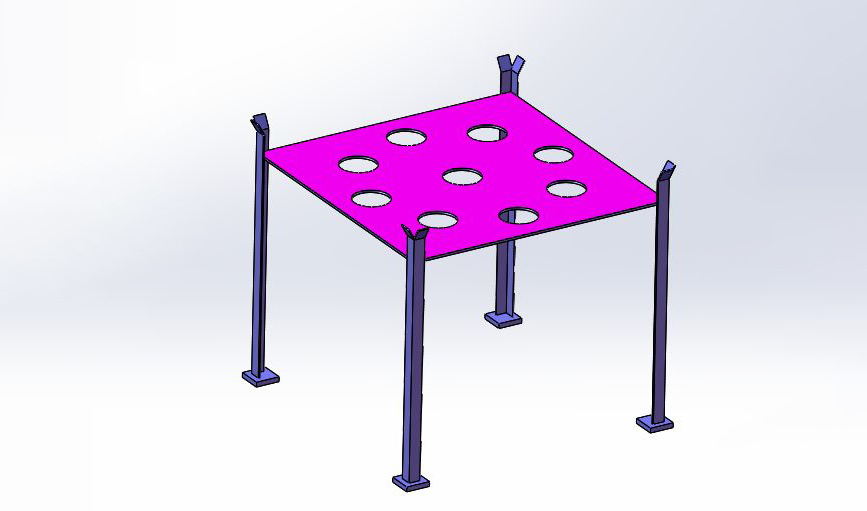

Nkata maka nchekwa nwa oge nke efere nkebi

Okwu Mmalite ọrụ

1. A na-emepụta nkata nwa oge maka efere nkebi ma na-eme atụmatụ ka a na-ebu ụzọ wepụ efere nkebi maka ịkwanye ma jiri nkebi nkebi maka oghere mee ihe mgbe e mesịrị;

2. A na-edobe efere nkebi nke loading na aka ma na-adịghị mma. Mgbe etinyechara efere nkewa n'ime nkata nchekwa nwa oge, robot nwere ike ịwepụ ma tinye ya nke ọma;

Tebụl nlele akwụkwọ ntuziaka

Nkọwa:

1. Tọọ ugboro ole akwụkwọ ntuziaka random maka usoro mmepụta dị iche iche, nke nwere ike na-ahụ maka ịdị irè nke nha n'ịntanetị;

2. Ntuziaka maka ojiji: Onye na-emegharị ihe ga-etinye workpiece ahụ n'ọnọdụ a na-etinye na tebụl nlele dịka ugboro ole ejiri aka tinye ya, wee jiri ọkụ na-acha uhie uhie mee ngwa ngwa. Onye nleba anya ga-pịa bọtịnụ iji bufee workpiece gaa na ebe nchekwa na mpụga nchekwa, wepụta workpiece maka nha ma chekwaa ya iche mgbe nhachara;

Ihe nchekwa

Ihe mejupụtara ya bụ profaịlụ aluminom dị fechaa (40 × 40) + ntupu (50 × 50), yana ihuenyo mmetụ na bọtịnụ nkwụsị ihe mberede nwere ike jikọta na ihe ndị na-echebe, na-ejikọta nchekwa na aesthetics.

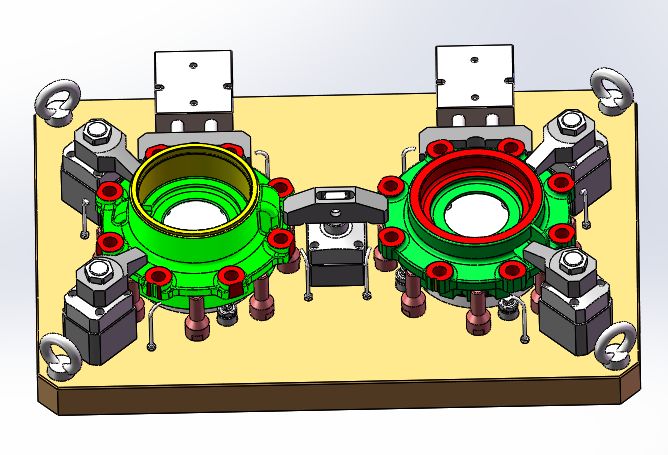

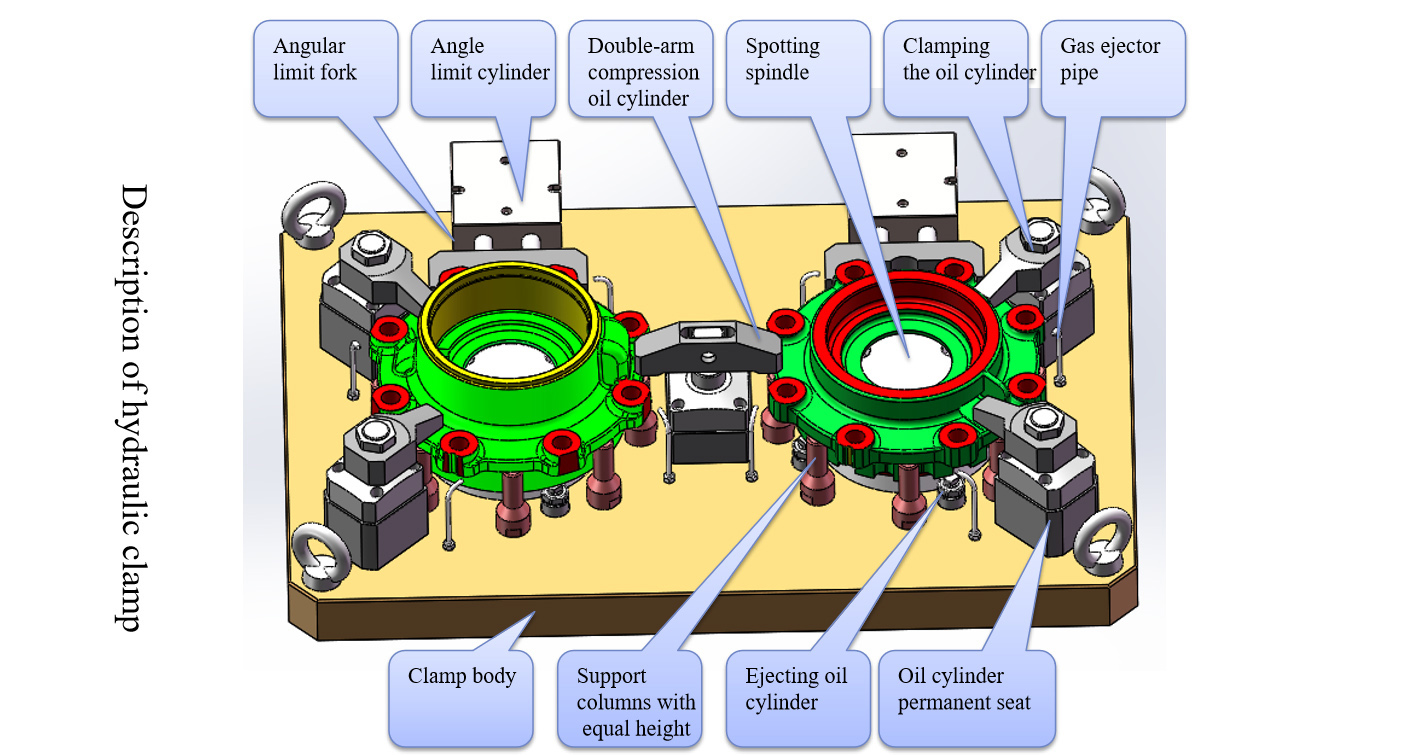

Okwu mmalite nke OP20 Hydraulic Fixture

Ntuziaka nhazi:

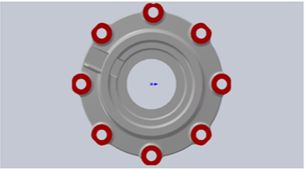

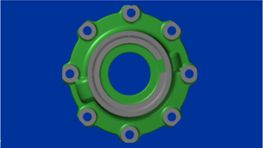

1. Were φ165 dị n'ime ime dị ka oghere ntọala, were D datum dị ka ụgbọ elu ala, ma buru n'elu arc nke onye isi nke oghere abụọ na-arị elu dị ka njedebe angular;

2. Na-achịkwa ịtọpụ na ịpị omume nke ịpị efere site n'iwu nke igwe ngwá ọrụ M iji mezue chamfering nhazi nke elu ụgbọelu nke arịọnụ oghere onyeisi, 8-φ17 arịọnụ oghere na abụọ nsọtụ nke oghere;

3. Ihe nrụnye ahụ nwere ọrụ nke nhazi, ntinye aka na-akpaghị aka, nchọpụta ikuku ikuku, nkwụsịtụ akpaaka, nkwụsị akpaka, mgbawa mgbawa na-akpaghị aka na nhichapụ nke ịtọgbọ elu datum;

Akụrụngwa chọrọ maka Production Line

1. The mmepụta akara akụrụngwa mwekota nwere ọrụ nke akpaka clamping na loosening, na-aghọta akpaka clamping na loosening ọrụ n'okpuru akara nke mgbaàmà nke manipulator usoro na-arụkọ ọrụ na loading na blanking edinam;

2. The skylight ọnọdụ ma ọ bụ akpaka ọnụ ụzọ modul ga-dobere maka metal efere nke mmepụta akara ngwá, na-ahazi na eletriki akara mgbaàmà na manipulator nkwurịta okwu nke anyị ụlọ ọrụ;

3. The mmepụta akara akụrụngwa nwere nkwurịta okwu na manipulator site na njikọ mode nke ibu-ibu njikọ (ma ọ bụ ụgbọ elu plọg);

4. The mmepụta akara akụrụngwa nwere esịtidem (nnyonye anya) ohere ibu karịa mma nso nke manipulator agba edinam;

5. Ngwá ọrụ ahịrị mmepụta ga-eme ka ọ bụrụ na ọ dịghị ihe mgbochi ígwè fọdụrụnụ n'elu ebe a na-etinye ihe nkedo ahụ. Ọ bụrụ na ọ dị mkpa, a ga-abawanye ikuku ikuku maka ihicha (chuck ga-atụgharị mgbe ị na-ehicha);

6. Ngwá ọrụ ahịrị mmepụta nwere ezigbo mgbawa mgbawa. Ọ bụrụ na ọ dị mkpa, a ga-agbakwunye ihe mgbakwunye mgbawa mgbawa mgbawa nke ụlọ ọrụ anyị;

7. Mgbe mmepụta ahịrị akụrụngwa chọrọ nkwụsị ziri ezi nke spindle igwe akụrụngwa, tinye ọrụ a ma nye akara eletrik kwekọrọ;

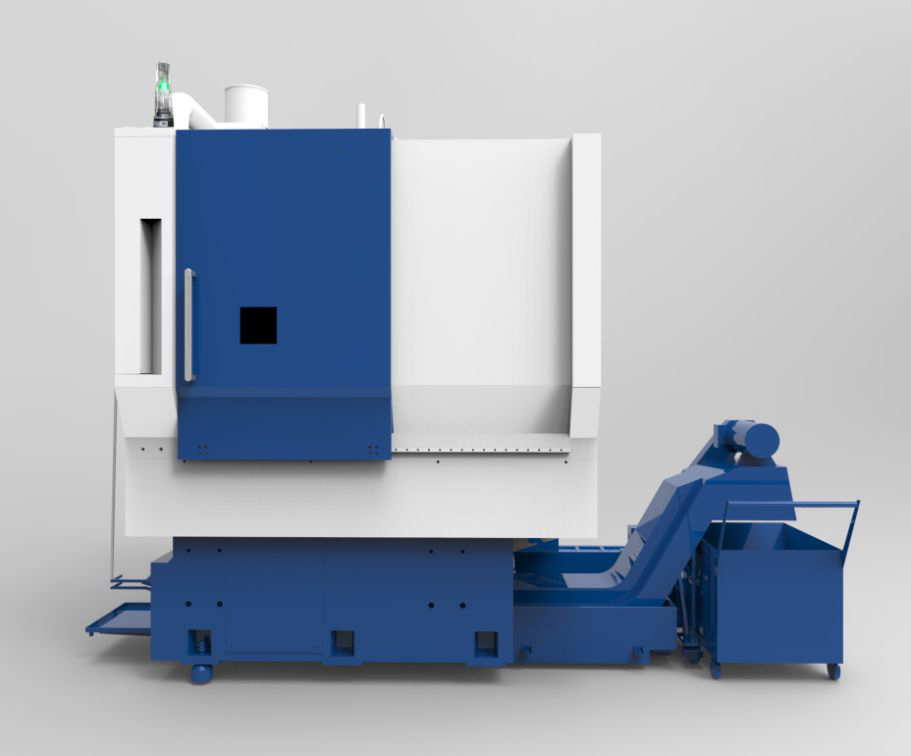

Okwu mmalite nke vetikal lathe VTC-W9035

VTC-W9035 NC vetikal lathe dabara adaba maka ịmegharị akụkụ ndị na-agbagharị agbagharị dị ka oghere oghere, flanges na shells nwere ụdị pụrụ iche, nke dabara adaba maka nkenke, ịchekwa ọrụ na ntụgharị nke ọma nke akụkụ dịka diski, oghere, diski breeki, ahụ mgbapụta, ozu valve na shells. The igwe ngwá ọrụ nwere uru nke ọma n'ozuzu rigidity, elu nkenke, nnukwu mwepụ ọnụego nke metal kwa nkeji oge, ezi ziri ezi njigide, elu pụrụ ịdabere, mfe mmezi, wdg na dịgasị iche iche nke ngwa. Mmepụta ahịrị, arụmọrụ dị elu na ọnụ ala dị ala.

| Ụdị ụdị | VTC-W9035 |

| Dayameta ntụgharị kachasị elu nke ahụ akwa | Φ900 mm |

| Dayameta ntụgharị kacha elu na efere na-amị amị | Φ590 mm |

| Dayameta ntụgharị kachasị nke workpiece | Φ850 mm |

| Ogologo ntụgharị kachasị nke workpiece | 700 mm |

| Oke ọsọ nke spindle | 20-900 r/min |

| Sistemu | FANUC 0i - TF |

| Kachasị strok nke X/Z axis | 600/800 mm |

| Ọsọ ọsọ ọsọ nke axis X/Z | 20/20 m/min |

| Ogologo, obosara na ịdị elu nke ngwá ọrụ igwe | 3550*2200*3950 mm |

| Ihe oru ngo | Nkeji | Oke | |

| Oke nhazi | njem axis X | mm | 1100 |

| njem axis X | mm | 610 | |

| njem axis X | mm | 610 | |

| Ebe dị anya site na imi mkpịsị mkpịsị aka ruo na oche ọrụ | mm | 150 ~ 760 | |

| Ụlọ ọrụ | Size nke workbench | mm | 1200×600 |

| Ibu ọrụ bench kacha | kg | 1000 | |

| T-groove (nha × ọnụọgụ × oghere) | mm | 18×5×100 | |

| Nri | Ọsọ inye nri ngwa ngwa nke axis X/Y/Z | m/min | 36/36/24 |

| Spindle | Ụdị ịkwọ ụgbọala | Ụdị eriri | |

| Spindle taper | BT40 | ||

| Ọsọ arụ ọrụ kacha | r/min | 8000 | |

| Ike (Akara/Kachasị) | KW | 11/18.5 | |

| Torque (Akara/Kachasị) | N·m | 52.5/118 | |

| Izi ezi | Ndokwasa axis X/Y/Z ziri ezi (ọkara aka mechiri emechi) | mm | 0.008 (mkpokọta ogologo) |

| X/Y/Z axis nkwugharị ziri ezi (ọkara aka mechiri emechi) | mm | 0.005 (mkpokọta ogologo) | |

| Magazin ngwaọrụ | Ụdị | Disc | |

| Ikike magazin ngwá ọrụ | 24 | ||

| Oke ngwá ọrụ kacha( Dayameta ngwá ọrụ zuru oke / dayameta ngwa ọrụ efu dị n'akụkụ / ogologo) | mm | Φ78/Φ150/ 300 | |

| Oke ngwá ọrụ dị arọ | kg | 8 | |

| Dị iche iche | Nrụgide ikuku | MPa | 0.65 |

| Ike ike | KVA | 25 | |

| N'ozuzu akụkụ nke igwe ngwá ọrụ (ogologo × obosara × ịdị elu) | mm | 2900×2800×3200 | |

| Ibu nke ngwá ọrụ igwe | kg | 7000 | |