Usoro Analysis nke Production Line

Die retrorei im technischen prozess

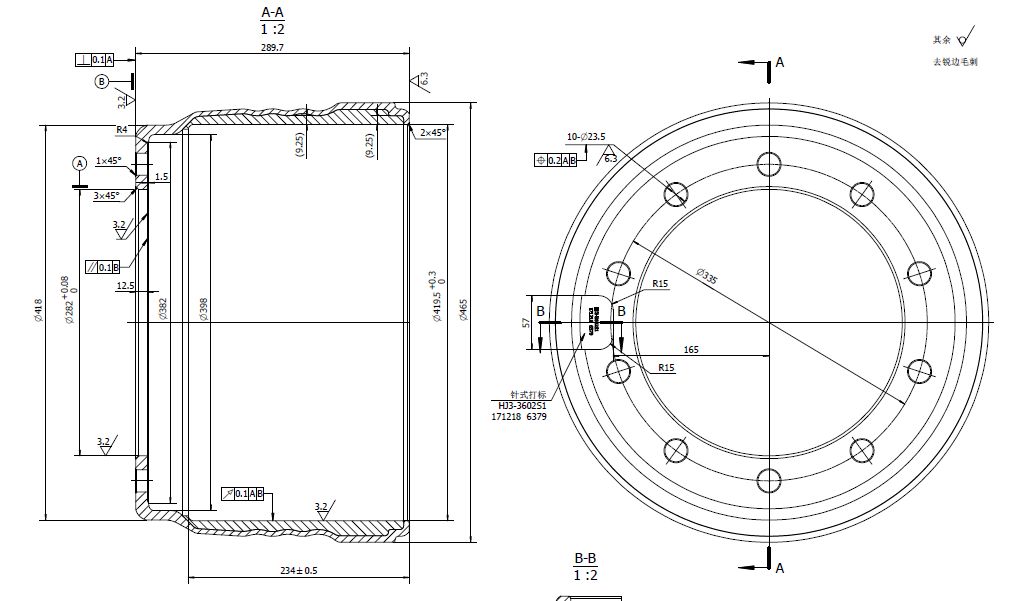

1. A na-anakwere usoro nkedo nke a na-atụgharị n'oge ntụgharị. Na-atụgharị akụkụ machining niile, gụnyere ala ala nke workpieces.

2. N'oge a na-egwupụta ihe, a ga-eji ihe nkedo hydraulic mee ihe iji chọta ebe dị n'ime ime nke Φ282 na ihu elu nke elu, na-agbanye 10-Φ23.5 na-agbanye oghere na chamfering n'akụkụ abụọ, na-egwepịa ebe akara pneumatic;

Ndepụta akụrụngwa

| OP10 machining Cycle ngụ oge | |||||||||||||||

| Nkọwa ụzọ |

| ||||||||||||||

| Onye ahịa | Ihe eji arụ ọrụ | 45 | Ihe nlere nke igwe igwe | Ebe nchekwa nọmba. | |||||||||||

| Aha ngwaahịa | Ịcha ngwá ọrụ aro welded akụkụ | Ihe osise Mba. | Ụbọchị nkwadebe | 2021.1.19 | Mepụtara site na | ||||||||||

| Usoro usoro | Mma No. | ọdịnaya igwe | Aha akụrụngwa | Ịcha dayameta | Ịcha ọsọ | Ọsọ ntụgharị | Nri kwa mgbanwe | nri site igwe ngwá ọrụ | Ọnụ ọgụgụ nke cuttings | Usoro ọ bụla | Oge nhazi | Oge efu | Kpuchie ma hapụ ya | Oge mgbanwe ngwá ọrụ | |

| Mba. | Mba. | Desoriptions | Ngwa | D mm | VcM/min | R pm | mm/Mkpu | mm/Nkeji | Oge | Ogologo mm | Nkeji | Nkeji | Nkeji | ||

| 1 | T01 | Mechie ihu n'elu nke ọma | 455,00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe siri ike DIA 419.5 ime ime, DIA 382 ihu nzọụkwụ na DIA 282 ime ime. | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Wepu ihu ngwụcha nke ọma | 455,00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | Kpochapụ nkenke DIA 419.5 nke dị n'ime, DIA 382 ihu nzọụkwụ na DIA 282 ime ime. | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300.0 | 185.39 | |||||

| 5 | T05 | Weghachi azụ azụ na ihu n'azụ ala | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Lata azụ azụ na kpomkwem ihu njedebe dị ala | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Nkọwa: | Oge igbu oge: | 437 | Nke abụọ | Oge iji jigide ihe nrụnye yana maka nbudata na ihe efu: | 15.00 | Nke abụọ | |||||||||

| Oge inyeaka: | 21 | Nke abụọ | Ngụkọta oge ọrụ igwe: | 472.81 | Nke abụọ | ||||||||||

| OP20 machining Cycle ngụ oge | |||||||||||||||

| Nkọwa ụzọ |  | ||||||||||||||

| Onye ahịa | Ihe eji arụ ọrụ | HT250 | Ihe nlere nke igwe igwe | Ebe nchekwa nọmba. | |||||||||||

| Aha ngwaahịa | Ịgba breeki | Ihe osise Mba. | Ụbọchị nkwadebe | 2021.1.19 | Mepụtara site na | ||||||||||

| Usoro usoro | Mma No. | ọdịnaya igwe | Aha akụrụngwa | Ịcha dayameta | Ịcha ọsọ | Ọsọ ntụgharị | Nri kwa mgbanwe | nri site igwe ngwá ọrụ | Ọnụ ọgụgụ nke cuttings | Usoro ọ bụla | Oge nhazi | Oge efu | Kpuchie ma hapụ ya | Oge mgbanwe ngwá ọrụ | |

| Mba. | Mba. | Desoriptions | Ngwa | D mm | VcM/min | R pm | mm/Mkpu | mm/Nkeji | Oge | Ogologo mm | Nkeji | Nkeji | Nkeji | ||

| 1 | T01 | Gwuo oghere 10-DIA 23.5 na-arị elu | Ngwuputa ala ala DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 compound reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 azụ orifice chamfering | DIA 22 reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Mpaghara Marking Milling | DIA 30 square ubu-egwe ọka | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Nkọwa: | Oge igbu oge: | 82 | Nke abụọ | Oge iji jigide ihe nrụnye yana maka nbudata na ihe efu: | 30 | Nke abụọ | |||||||||

| Oge inyeaka: | 104 | Nke abụọ | Ngụkọta oge ọrụ igwe: | 233.00 | Nke abụọ | ||||||||||

Okwu Mmalite na Production Line

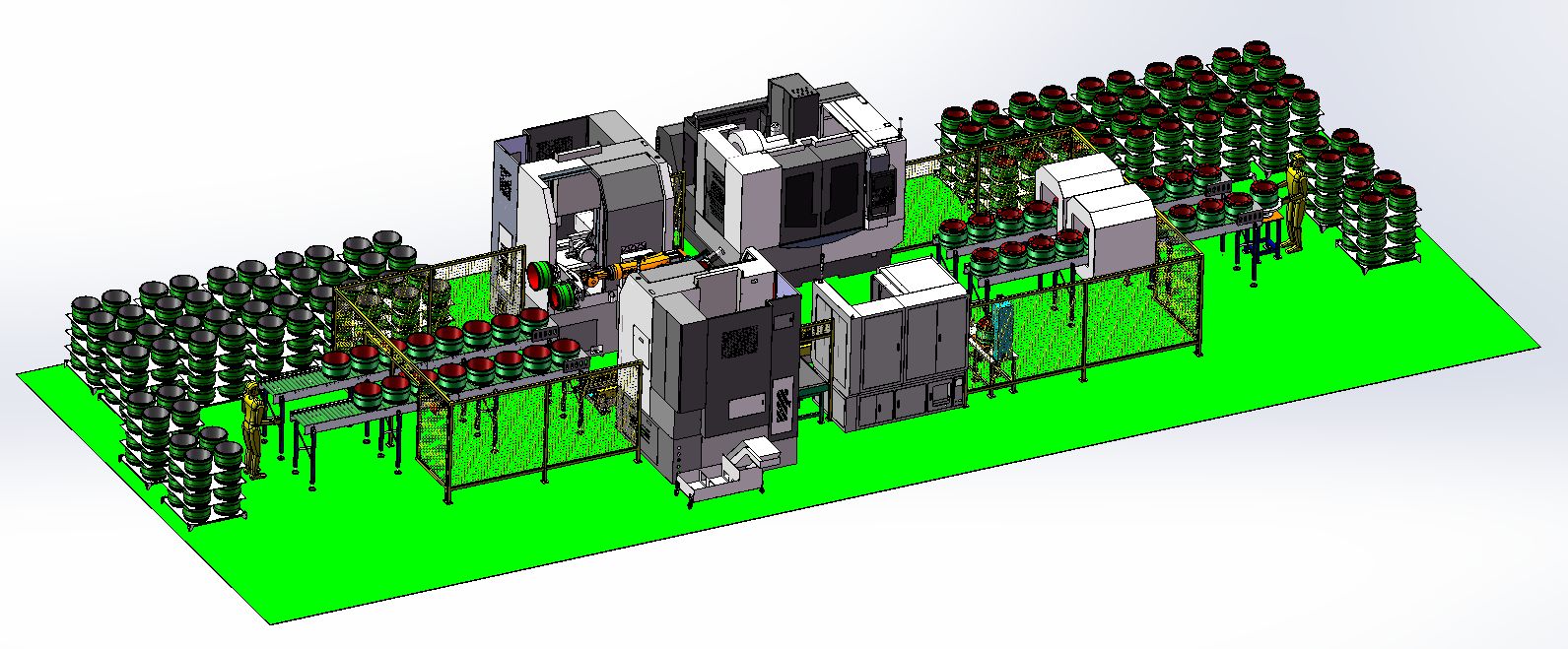

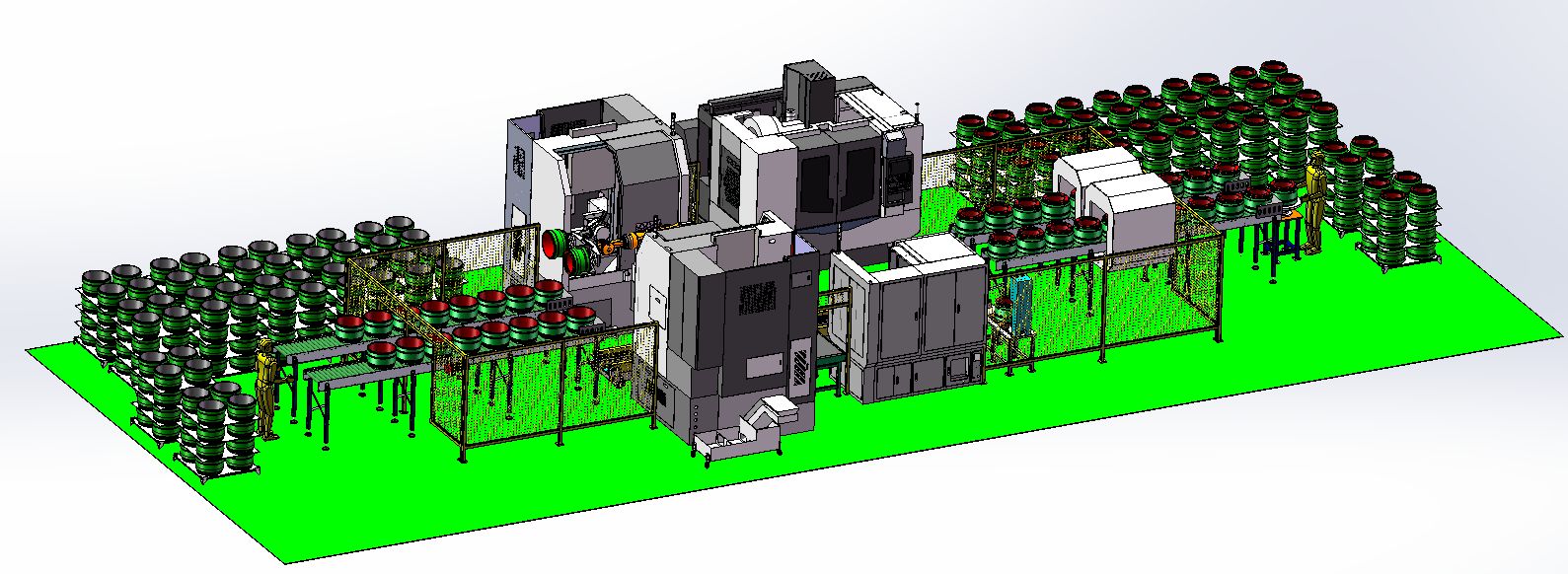

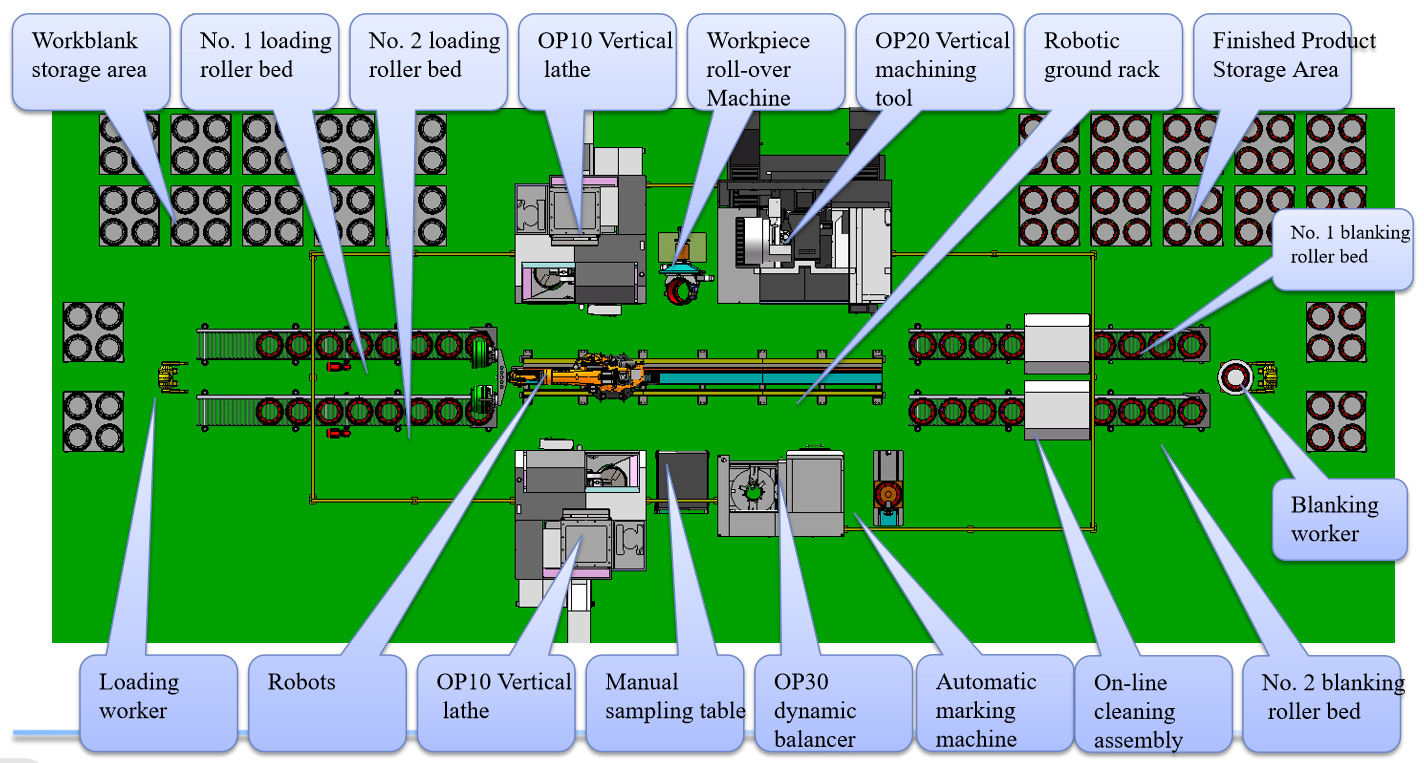

Nhazi nke Line Production

Okwu Mmalite na Production Line

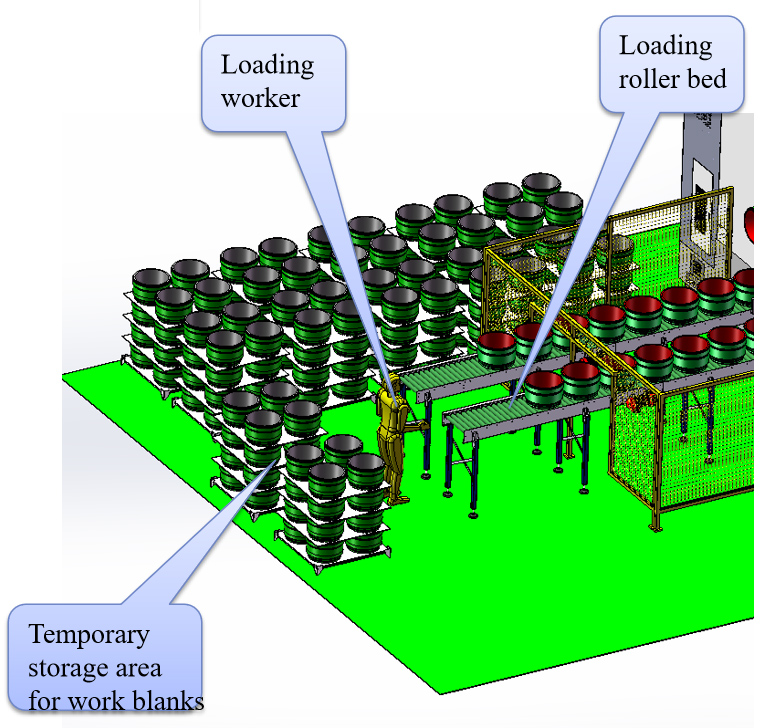

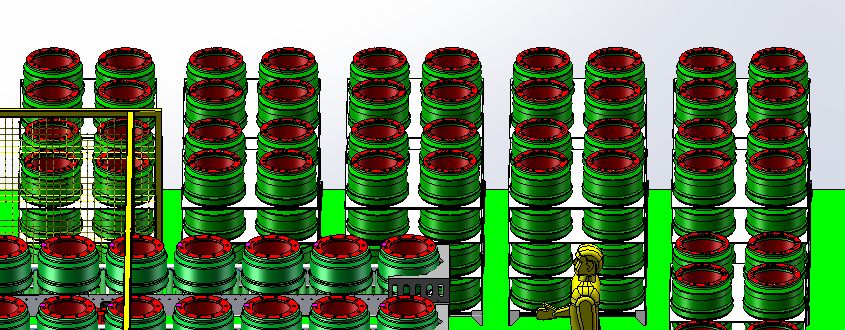

The mmepụta akara mejupụtara 1 loading unit, 1 lathe machining unit na 1 blanking unit. Robots na-ebufe ihe n'etiti ọdụ ụgbọ mmiri dị n'ime nkeji ọ bụla. Forklifts na-edobe nkata n'ihu nkeji nbudata na oghere; The mmepụta akara na-ekpuchi ebe: 22.5m×9m

Nkọwa nke ahịrị mmepụta

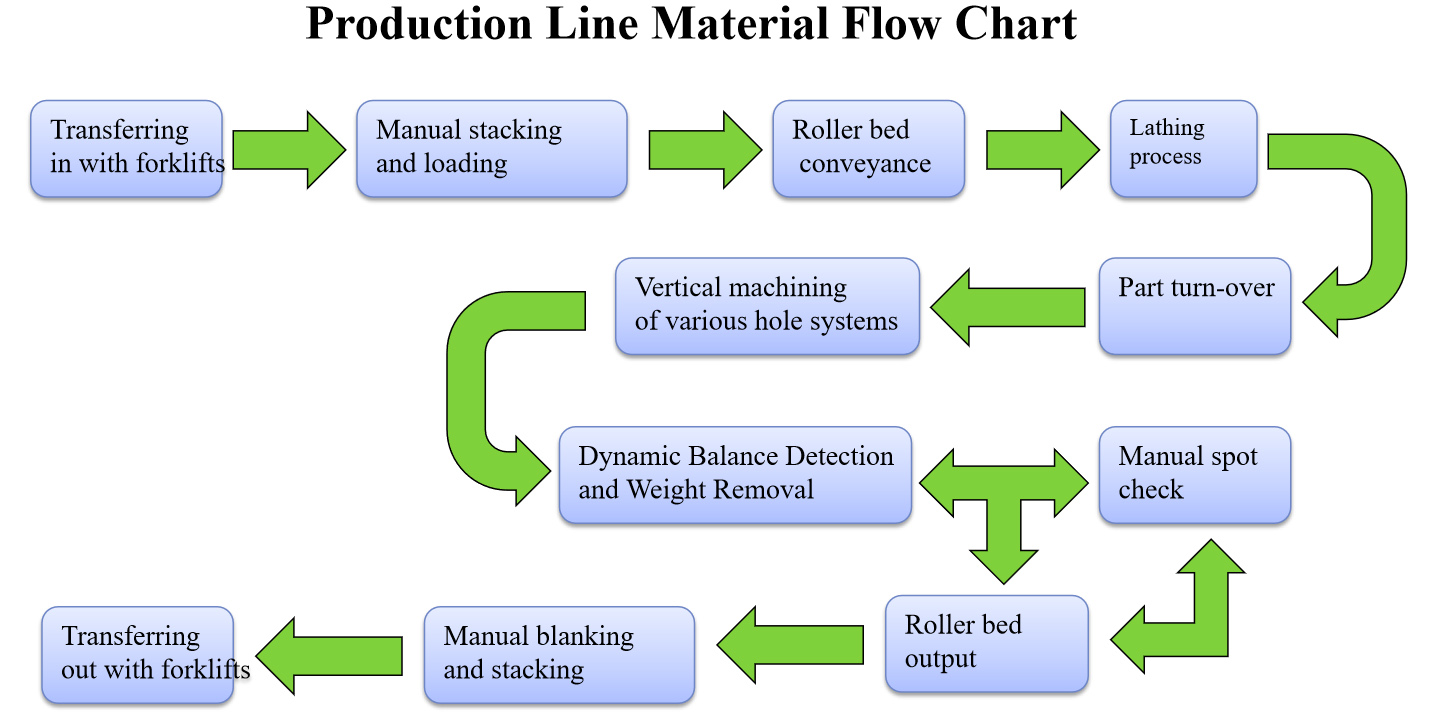

1. A na-ebufe oghere ọrụ na ọdụ ụgbọ mmiri site na forklifts, jiri aka na-ebuli ya na akwa akwa, ma zigara ya n'ọdụ ụgbọ mmiri site na rollers. A na-emecha ihe eji eme ihe na igwe na-eme ka igwe na-edozi ahụ na usoro lathe, usoro mpịakọta na usoro mkpọpu na igwe igwe. A na-eziga ngwaahịa ndị emechara n'ọdụ ụgbọ mmiri ndị na-adịghị ahụkebe site na akwa akwa akwa, ma zipụ ya site na forklift mgbe ejiri aka na-ebuli na ikpokọta;

2. A ga-edobe ihuenyo ihe ngosi eletrọnịkị buru ibu na ahịrị nnyefe ngwa ngwa iji melite ma gosipụta ozi nke mmepụta, ngwaahịa ndị na-adịghị mma na ụbọchị mmepụta nchekwa na oge;

3. A ga-enye eriri nnyefe ahụ ọkụ ịdọ aka ná ntị na nkeji ọ bụla, nke nwere ike igosipụta ozi dịka ihe nkịtị, enweghị ihe na egwu;

4. Akara akpaaka na-anabata ọnọdụ nhazi nhazi na ọnọdụ wiring multi-unit, na nhazi mgbanwe, dabara adaba maka ihe dị iche iche chọrọ ndị ahịa;

5. Nabata robot nkwonkwo maka nbudata na oghere, nke nwere nkwụsi ike dị elu, mmezi dị mma na ogologo ndụ ọrụ;

6. Obere ọchịchọ maka ndị ọrụ. Ihe ndị ọrụ na-achọ kwa ụbọchị maka mgbanwe ọ bụla nke ahịrị akpaka a bụ ndị a:

Forkliftman 1 ~ 2 ndị mmadụ (na-ahụ maka ibuli, ịkwanye na ibufe oghere ọrụ / ngwaahịa emechara)

Onye injinia na-elekọta mmadụ 1 (onye na-ahụ maka nlekọta oge niile-mmanụ na ndị na-egbu mmiri, wdg)

7. The akpaka akara nwere ike extensibility. Dị ka agwakọta waya machining, workpiece traceability na ndị ọzọ na-arụ ọrụ, na ọnụ ala mgbasa ozi;

Ngalaba na-ebunye

1. The loading roller bed line nwere ike ịchekwa 12 × 16 = 192 iberibe; 2. Jiri aka meghee ngwugwu ahụ wee bulite ya na akwa akwa akwa ma ziga ya na ebe a na-ebu ibu site na onye na-ebu ibu; 3. Mgbe emepechara ngwugwu ahụ, a ga-ejigide traị ahụ na-adịghị ahụkebe ma tinye ya n'ahịrị oghere nke trays na-adịghị efu, na-agbanye n'ime 8 n'ígwé, a ga-eji aka wepụ ihe na-adịghị ahụkebe tray ma tinye ya na ebe nchekwa;1. The loading roller bed line nwere ike ịchekwa 12 × 16 = 192 iberibe;

2. Jiri aka meghee ngwugwu ahụ wee bulite ya na akwa akwa akwa ma ziga ya na ebe a na-ebu ibu site na onye na-ebu ibu;

3. Mgbe emepechara ngwugwu ahụ, a ga-ejigide traị ahụ na-adịghị ahụkebe ma tinye ya n'ahịrị oghere nke oghere ndị na-adịghị efu, na-agbanye n'ime 8 n'ígwé, a ga-ewepụkwa ihe nkedo na-abaghị uru na aka ma tinye ya na ebe nchekwa;

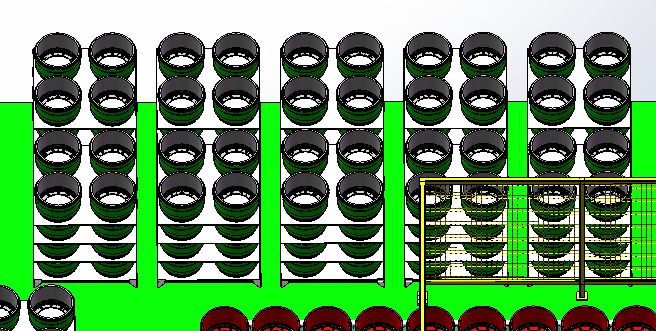

Okwu mmalite na-arụ ọrụ oghere oghere

1. Otu nchịkọta nke 16 iberibe na 4 n'ígwé na mkpokọta, na nkebi efere n'etiti ọ bụla oyi akwa;

2. Ngwunye oghere ọrụ nwere ike ịchekwa iberibe 160;

3. A na-atụ aro pallet ka onye ahịa kwadebe ya. Ihe a chọrọ: (1) ezigbo nkwụsi ike na ịdị larịị (2) inwe ike iji rọbọt mechie ya.

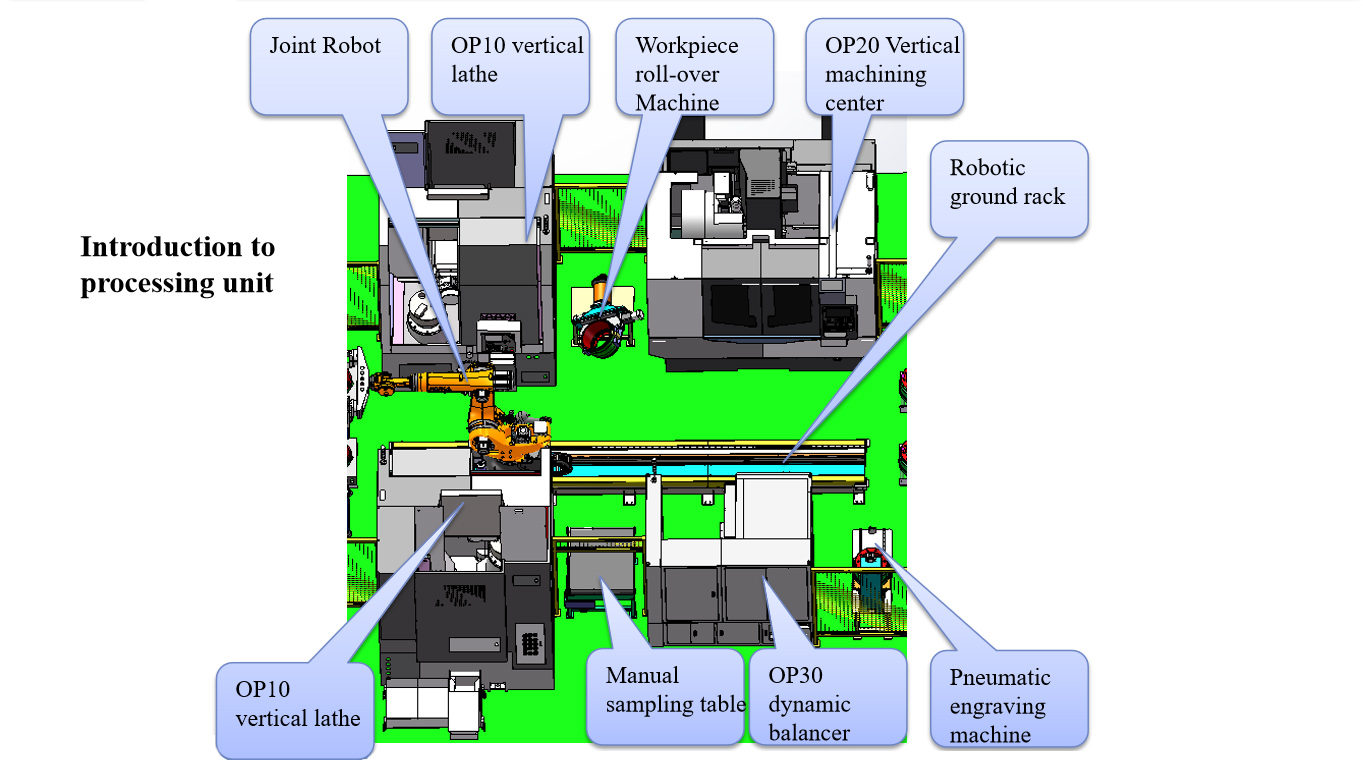

Okwu mmalite nke nhazi unit

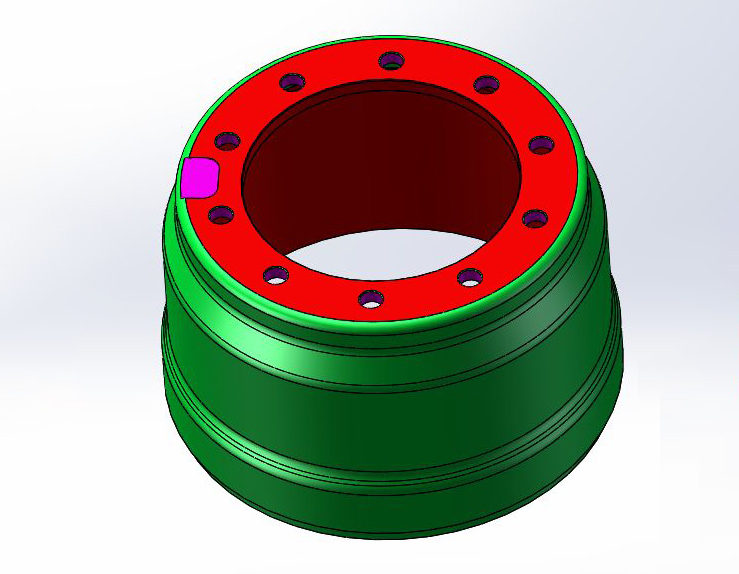

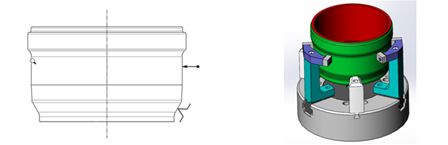

1. The lathing usoro mejupụtara abụọ vetikal lathes, Nke 1 robot na robot ala ogbe, nke undertakes na machining nke elu gburugburu, n'ime oghere nzọụkwụ elu na ọgwụgwụ ihu nke akụkụ;

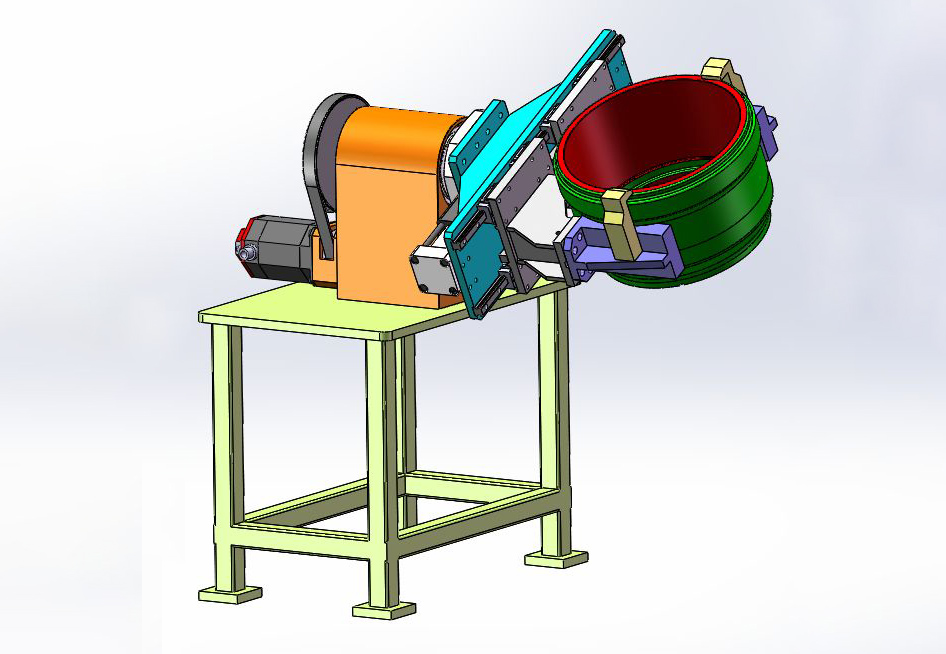

2. Roll-over station mejupụtara 1 igwe na-atụgharị n'elu igwe, nke na-arụ ọrụ ntụgharị akpaka nke akụkụ;

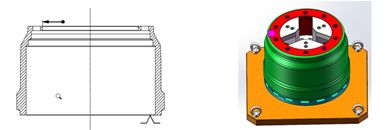

3. Usoro nke ịkụ ala na igwe nri nwere 1 vertical machining center na otu Robot No. 2, nke na-arụ ọrụ nhazi nke oghere ntinye na akara akara nke akụkụ a.

4. The ike itule na arọ iwepụ usoro mejupụtara a vetikal dynamic balancer, nke na-eme ihe ike itule nchọpụta na arọ wepụ nke akụkụ;

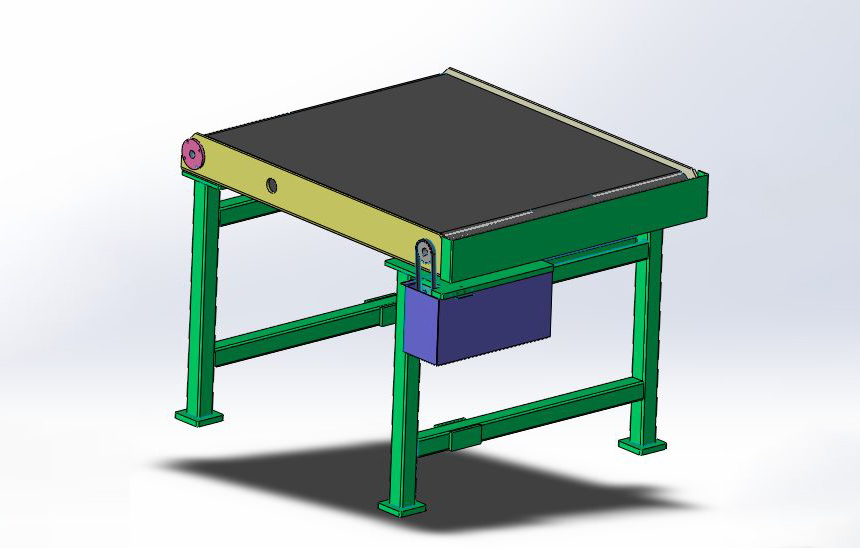

5. Ebe a na-enyocha ntụpọ akwụkwọ ntuziaka nwere eriri eriri, nke na-ebufe akụkụ ebe a na-enyocha ma jiri ya dị ka ikpo okwu nyocha;

6. Ebe ọrụ nke igwe ihe osise pneumatic na-arụ ọrụ nke ịde na akara ngwaahịa niile;

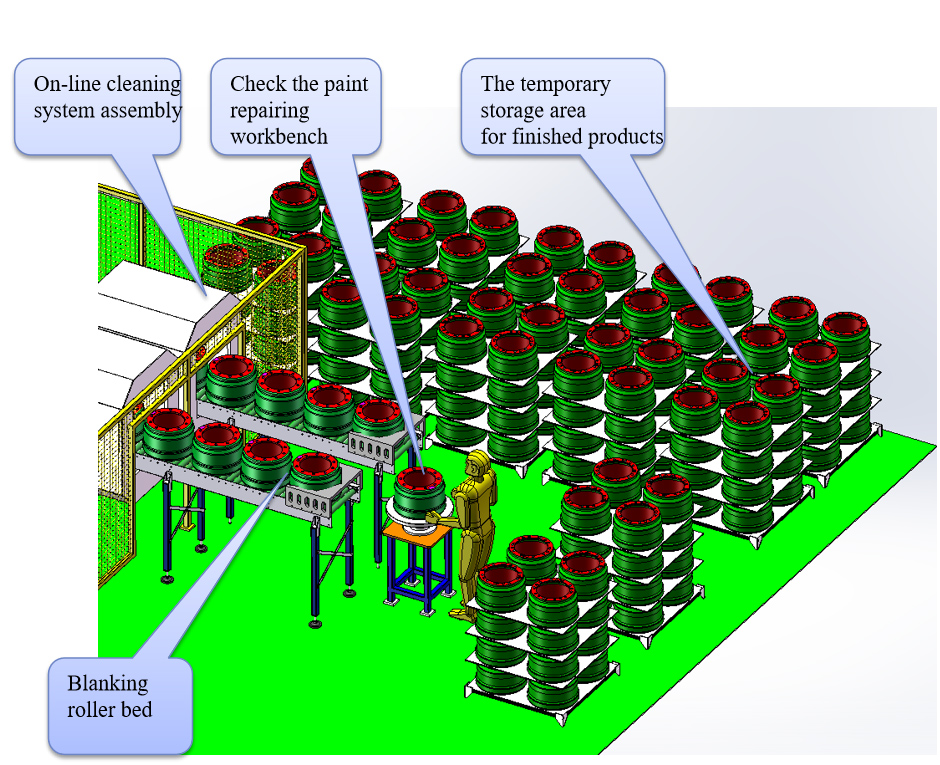

Okwu mmalite nke otu oghere

1. The loading roller bed line nwere ike ịchekwa 12 × 16 = 192 iberibe;

2. A na-ebufe trays na efere nkewa na ebe a na-ebufe ihe na ebe a na-adịghị ahụ anya site na forklift;

3. A na-ebufe ngwaahịa ndị a rụchara n'ọdụ ụgbọ mmiri na-ebufe ihe na-ebugharị, ma na-ebuli ya ma na-akwakọba ya na aka ma bufee ya na forklift;

Okwu mmalite nke nchịkọta ngwaahịa emechara

1. Otu nchịkọta nke 16 iberibe na 4 n'ígwé na mkpokọta, na nkebi efere n'etiti ọ bụla oyi akwa;

Enwere ike ịchekwa iberibe 2.192 na nchịkọta ngwaahịa emechara;

3. A na-atụ aro pallet ka onye ahịa kwadebe ya. Ihe a chọrọ: (1) ezigbo nkwụsi ike na ịdị larịị (2) inwe ike iji rọbọt mechie ya.

Okwu mmalite nke isi ọrụ akụrụngwa nke mmepụta ahịrị

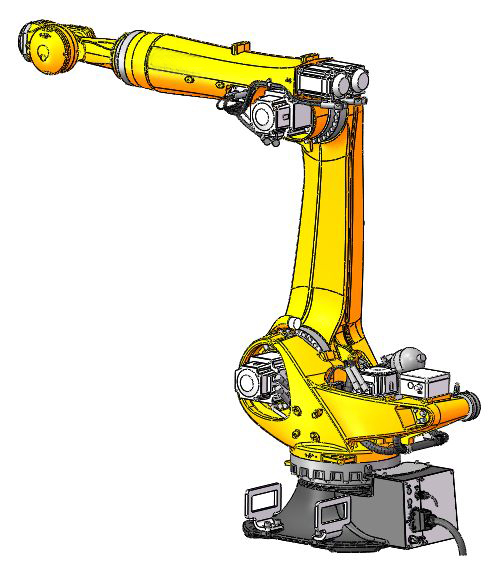

Okwu Mmalite nke Nrụpụta na Ịhazi Arọ Mwepu Nkebi Robot

Robot Chenxuan: SDCX-RB08A3-1700

| Data ndabere | |

| Ụdị | SDCX-RB08A3-1700 |

| Ọnụọgụ anyụike | 6 |

| Mkpuchi kacha | 3100mm |

| Nwee ike ikwughachi (ISO 9283) | ± 0.05mm |

| Ibu | 1134 n'arọ |

| Nhazi nchedo nke robot | Ogo nchekwa, IP65 / IP67nkwojiaka n'ahịrị(IEC 60529) |

| Nkwanye ọnọdụ | N'uko ụlọ, ikike n'akuku echiche ≤ 0º |

| Imecha elu, ihe osise | Okpokoro ntọala: ojii (RAL 9005) |

| Ọnọdụ okpomọkụ | |

| Ọrụ | 283K ruo 328K (0 °C ruo +55 Celsius) |

| Nchekwa na njem | 233 K ruo 333 K (-40 Celsius C ruo +60 Celsius) |

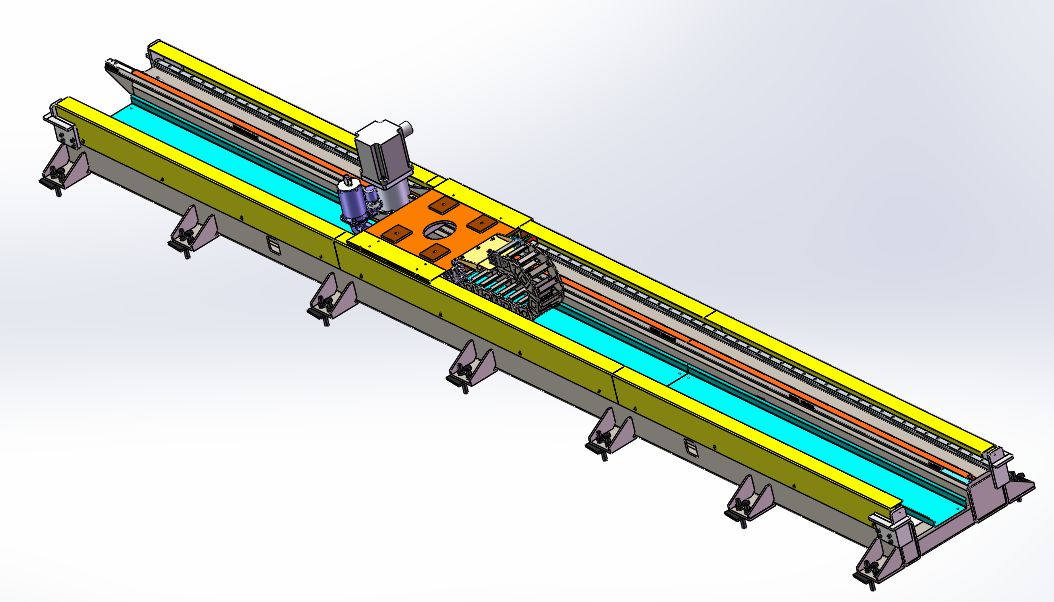

Okwu Mmalite nke Robot Njem Axis

Ihe mejupụtara ya bụ robot nkwonkwo, servo moto mbanye na pinion na rack drive, nke mere na robọt ahụ nwere ike ịmegharị mmegharị azụ azụ na azụ. Ọ na-aghọta ọrụ nke otu robot na-eje ozi ọtụtụ igwe ngwaọrụ na gripping workpieces n'ọtụtụ ọdụ na nwere ike dịkwuo na-arụ ọrụ mkpuchi nke nkwonkwo robots;

Njem egwu na-emetụta ntọala welded na ọkpọkọ nchara ma na-ebugharị ya site na servo moto, pinion na rack drive, na-abawanye mkpuchi na-arụ ọrụ nke robot nkwonkwo ma na-emeziwanye ọnụọgụ nke robot;

A na-etinye egwu njem na ala;

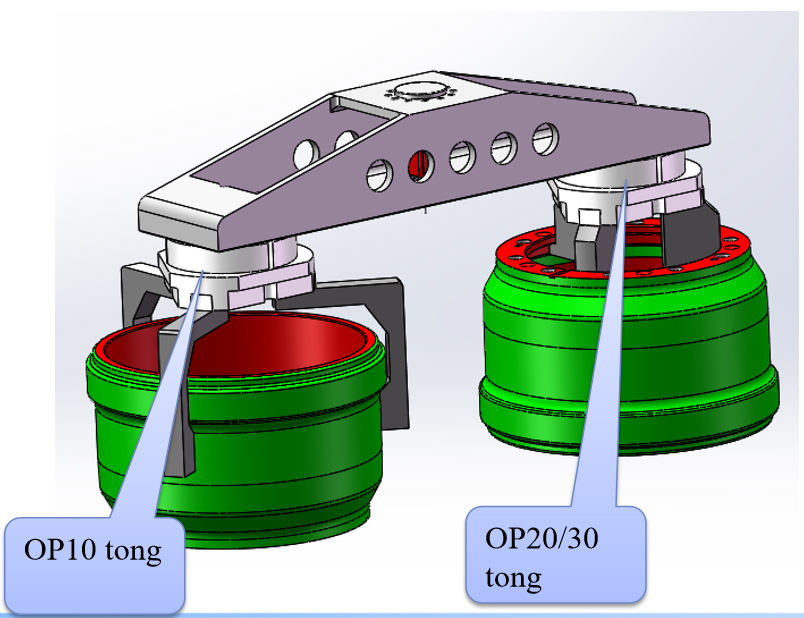

Mmalite nke ngwungwu igwe na-ebunye na igwe anaghị agba nchara

Nkọwa:

1. Dị ka kwa njirimara nke akụkụ a, anyị na-anakwere atọ-claw mpụga ife elu;

2. A na-eji usoro nchọpụta ọnọdụ ọnọdụ na ihe mmetụta nrụgide chọpụta ma ọnọdụ njigide na nrụgide nke akụkụ bụ ihe nkịtị;

3. The usoro na-onwem na a pressurizer, na workpiece agaghị ada apụ na a obere oge na ikpe nke ike ọdịda na gas ebipụ nke isi ikuku sekit;

Okwu Mmalite nke Igwe ntugharị akpaaka

Nkọwa:

Ihe mejupụtara usoro a bụ nke etinyere n'usoro, nkwado ntọala na mgbakọ pneumatic tong. Ọ nwere mgbochi rụrụ na mgbochi idobe ọrụ mgbe ikuku cutoff, na ike na-aghọta 180 ° mpịakọta n'elu nke akara workpieces;

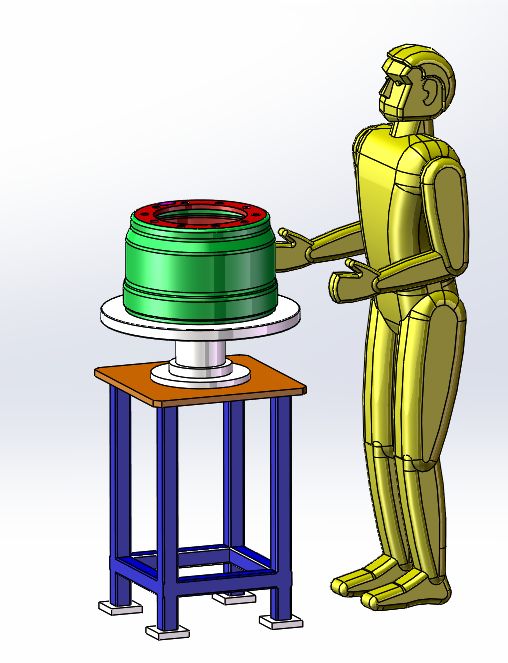

Okwu mmalite na oche nlele ntụpọ aka

Nkọwa:

1. Tọọ ugboro ole akwụkwọ ntuziaka random maka usoro mmepụta dị iche iche, nke nwere ike na-ahụ maka ịdị irè nke nha n'ịntanetị;

2. Ntuziaka maka ojiji: Onye na-emegharị ihe ga-etinye workpiece ahụ n'ebe a na-edebe ebe a na-elele bench dịka ugboro ole a na-etinye aka, ma jiri ọkụ na-acha uhie uhie mee ngwa ngwa. Onye nleba anya ga-pịa bọtịnụ iji bufee workpiece gaa na nchekwa na mpụga nchekwa, wepụta workpiece maka nha ma weghachite ya n'ihe ndina rola mgbe atụchara;

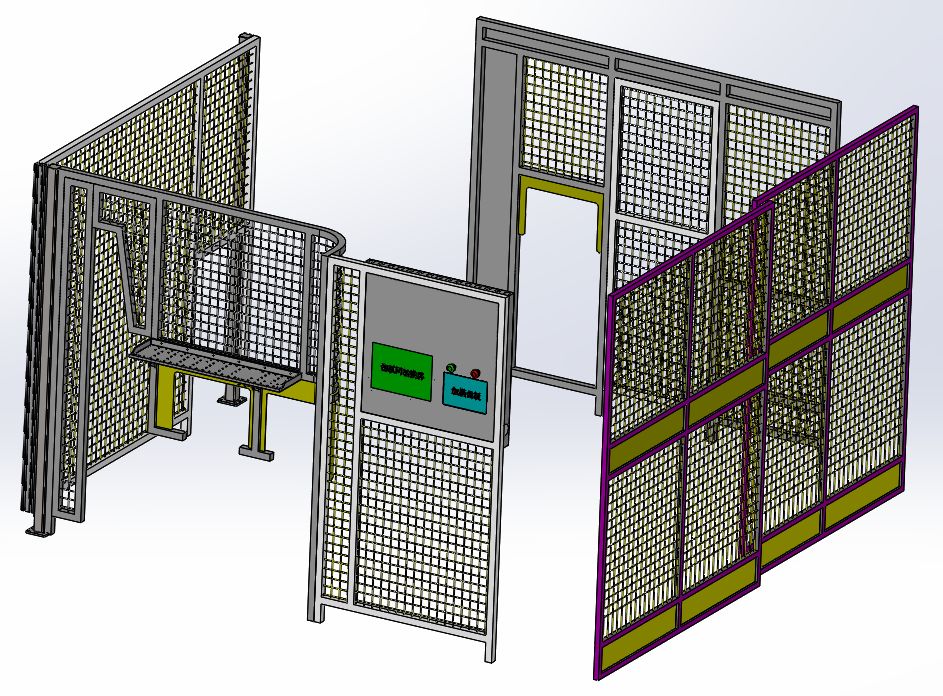

Ihe nchekwa

Ihe mejupụtara ya bụ profaịlụ aluminom dị fechaa (40 × 40) + ntupu (50 × 50), yana ihuenyo mmetụ na bọtịnụ nkwụsị ihe mberede nwere ike jikọta na ihe ndị na-echebe, na-ejikọta nchekwa na aesthetics.

Okwu Mmalite nke Ụlọ Ọrụ Nyocha maka ịrụzi agba

Nkọwa:

Usoro ahụ bụ nke etinyere na etiti na ntụgharị ntụgharị. Ndị ọrụ ahụ na-ebuli ngwaahịa ndị emechara na ntụgharị, na-atụgharị ntụgharị, lelee ma enwere ihe mgbagwoju anya, ncha na ihe ndị ọzọ, na-arụkwa ọrụ n'oge na-adịghị mma na ntụpọ na agba;