Nchịkọta oru ngo

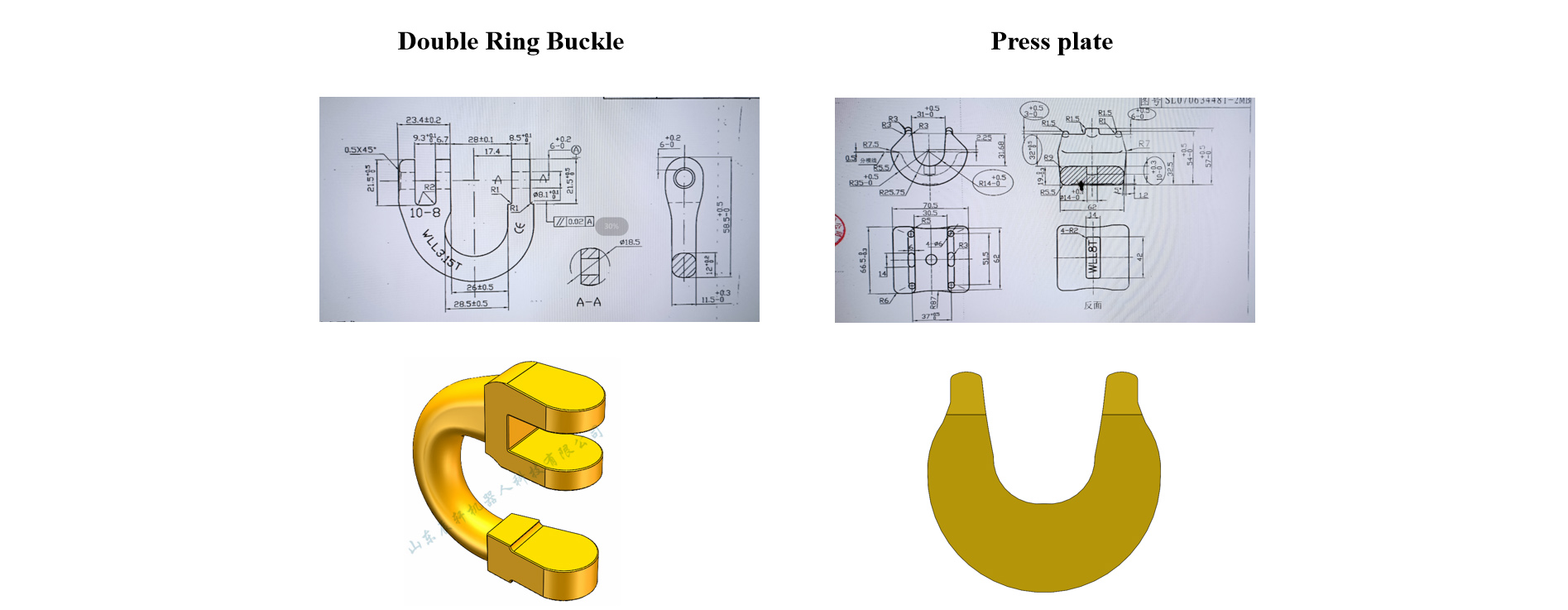

Eserese Workpiece: N'okpuru eserese CAD nyere site na Party A chọrọ nka nka: Na-ebuba ọnụọgụ nchekwa silo ≥ nrụpụta ikike n'otu elekere

| Ụdị arụ ọrụ | Nkọwapụta | Oge nhazi | Ọnụ ego nchekwa / elekere | Ọnụọgụ nke wires | Ihe achọrọ |

| SL-344 efere efere | 1T/2T/3T | 15 | 240 | 1 | Dakọtara |

| 5T/8T | 20 | 180 | 1 | Dakọtara | |

| SL-74 eriri mgbanaka okpukpu abụọ | 7/8-8 | 24 | 150 | 2 | / |

| 10-8 | 25 | 144 | 2 | / | |

| 13-8 | 40 | 90 | 2 | / | |

| 16-8 | 66 | 55 | 1 | / | |

| 20-8 | 86 | 42 | 2 | / |

Eserese workpiece, ụdị 3D

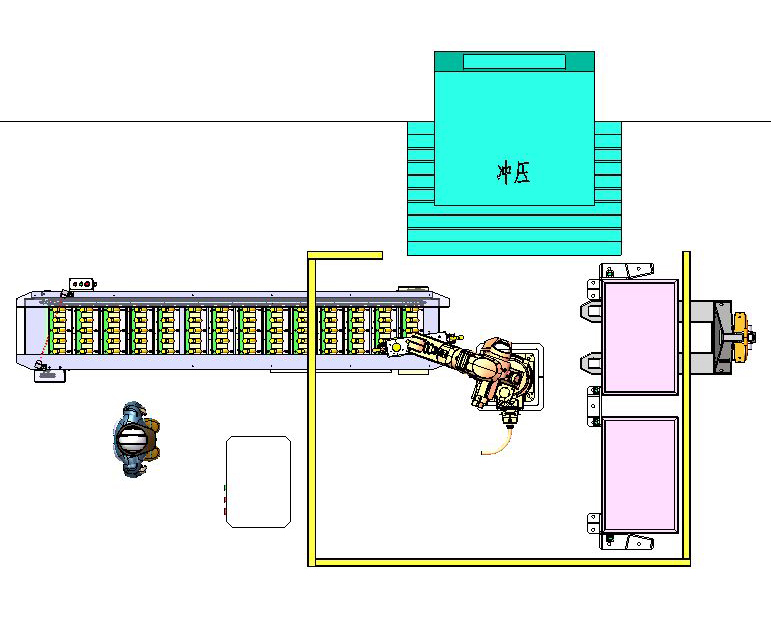

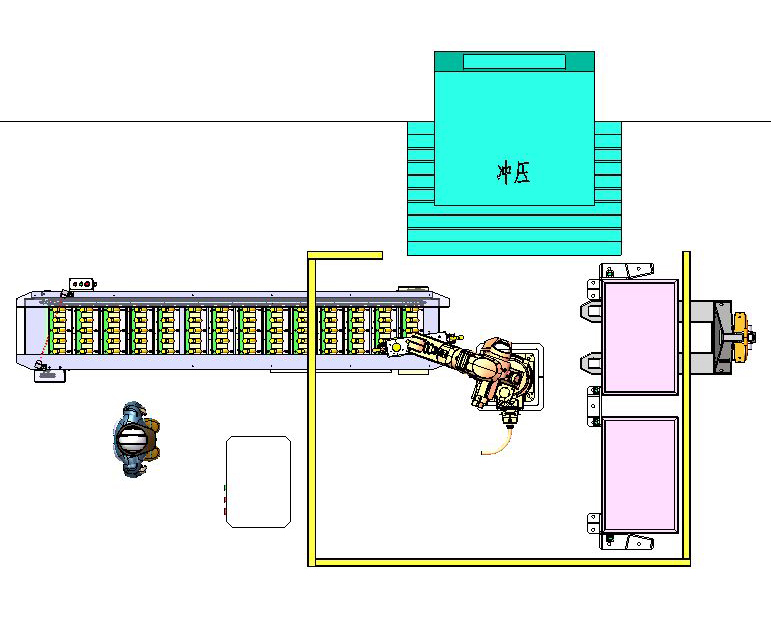

Nhazi atụmatụ

Nkọwa: Nkọwa zuru ezu nke ọrụ ala ga-adabere na nhazi ahụ.

Ndepụta akụrụngwa

Nkata maka nchekwa nwa oge nke efere nkebi

| S/N | Aha | Ụdị No. | Ọnụọgụ. | Okwu |

| 1 | Robots | XB25 | 1 | Chenxuan (gụnyere ahụ, kabinet njikwa na onye ngosi) |

| 2 | Robot tong | Nhazi | 1 | Chenxuan |

| 3 | Robot ntọala | Nhazi | 1 | Chenxuan |

| 4 | Sistemụ Njikwa Eletriki | Nhazi | 1 | Chenxuan |

| 5 | Na-ebu ibu | Nhazi | 1 | Chenxuan |

| 6 | Nkpuchi nchekwa | Nhazi | 1 | Chenxuan |

| 7 | Ngwaọrụ nchọpụta ọnọdụ etiti ihe | Nhazi | 2 | Chenxuan |

| 8 | okpokolo agba oghere | / | 2 | Onye kwadoro Party A |

Nkọwa: Tebụl na-egosi ndepụta nhazi nke ụlọ ọrụ onye ọ bụla.

Nkọwa nka nka

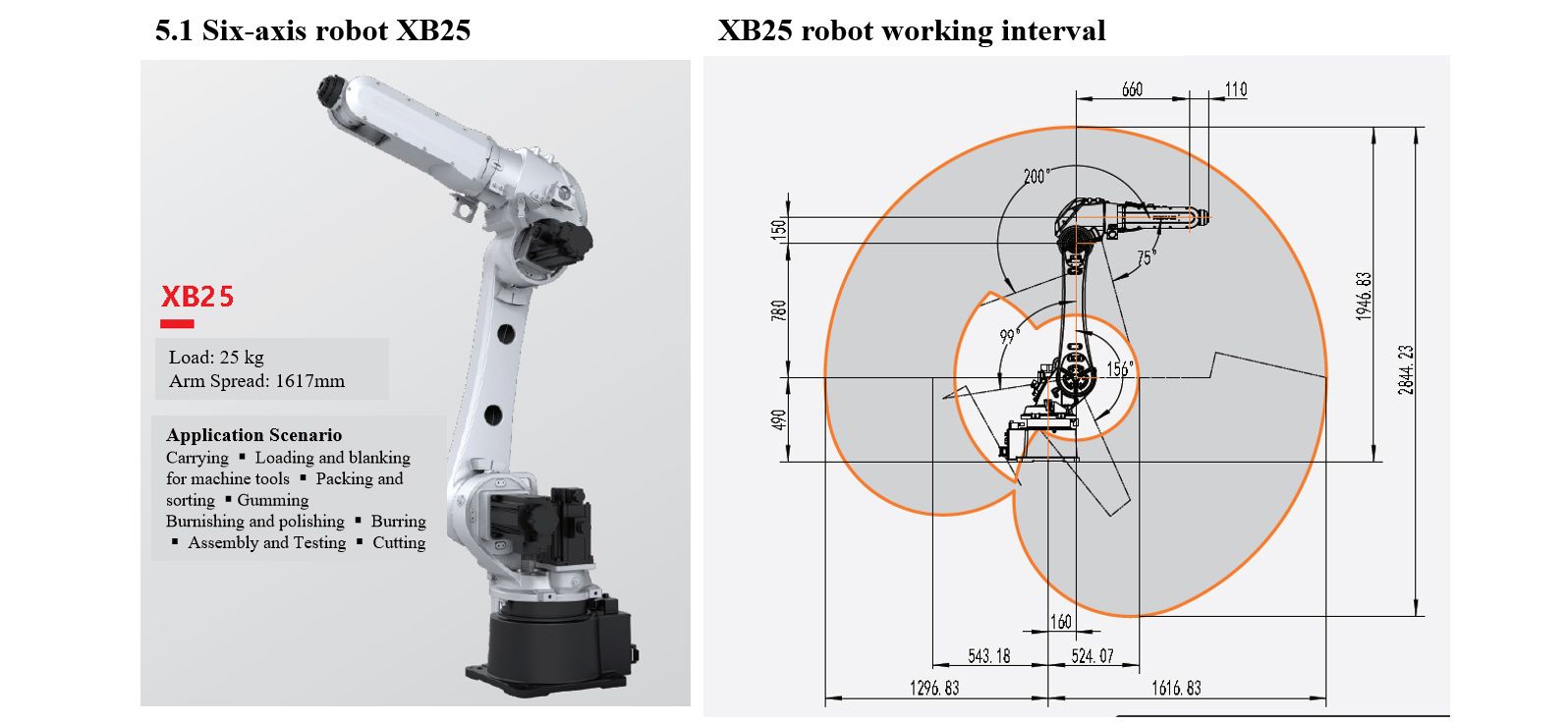

Robot XB25 nwere axis isii

Roboter XB25 als grundlegende paramita

| Ụdị No. | Ogo nke nnwere onwe | Ibu nkwojiaka | Radius arụ ọrụ kacha | ||||||||

| XB25 | 6 | 25kg | 1617 mm | ||||||||

| Ndokwa ugboro ugboro ziri ezi | Uka ahụ | Ọkwa nchekwa | Ụdị nwụnye | ||||||||

| ± 0.05mm | Ihe ruru. 252kg | IP65 (aka IP67) | Ala, kwụsịtụrụ | ||||||||

| Isi iyi ikuku agbakwunyere | Isi mmalite mgbaàmà agbakwunyere | Egosiri ike nke transformer | Onye njikwa dakọtara | ||||||||

| 2-φ8 ọkpọkọ ikuku (Ogwe 8, valvụ solenoid maka nhọrọ) | 24-ọwa mgbama (30V, 0.5A) | 9.5kVA | XBC3E | ||||||||

| Oke ngagharị | Ọsọ kacha | ||||||||||

| Ogwe 1 | Shaft 2 | Ogwe 3 | Ogwe 4 | Ngwunye 5 | Nkwonkwo 6 | Ogwe 1 | Shaft 2 | Ogwe 3 | Ogwe 4 | Ngwunye 5 | Nkwonkwo 6 |

| +180°/-180° | +156°/-99° | +75°/-200° | +180°/-180° | +135°/-135° | +360°/-360° | 204°/S | 186°/S | 183°/S | 492°/S | 450°/S | 705°/S |

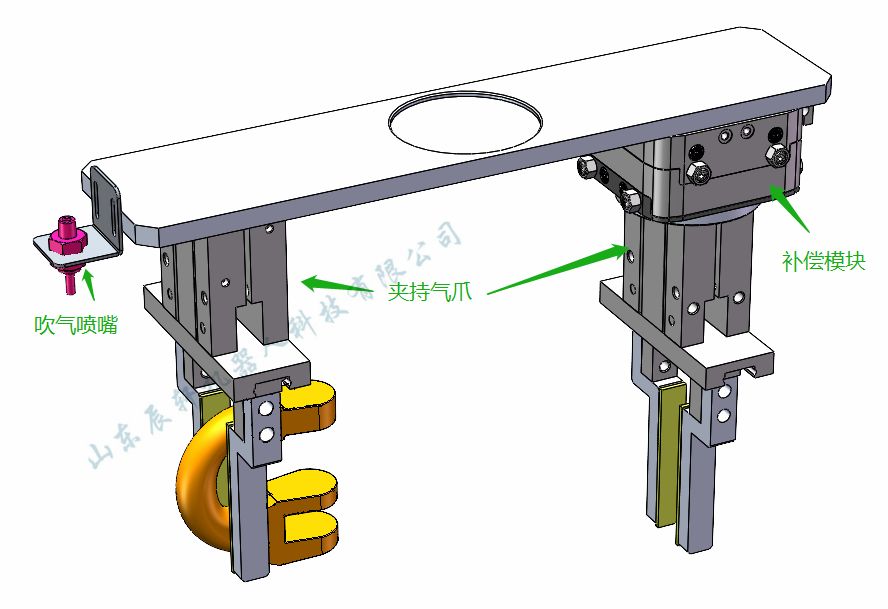

Robot tong

1. Nhazi ọdụ abụọ, ntinye ntinye na oghere, na-enwe ike ịghọta ọrụ ntinye ngwa ngwa;

2. Naanị ọdabara na mwekota workpieces nke kpọmkwem nkọwa, na tong bụ naanị dakọtara na clamping nke yiri workpieces n'ime a ụfọdụ nso;

3. Ịkwụsị ike na-ejide n'aka na ngwaahịa ahụ agaghị ada n'oge dị mkpirikpi, nke dị mma na ntụkwasị obi;

4. Otu ìgwè nke pneumatic nozzles na-agba ọsọ nwere ike izute ọrụ ịfụ ikuku na etiti machining;

5. A ga-eji ihe ndị dị nro nke polyurethane mee ihe maka ịpịa mkpịsị aka iji zere ịkụnye nke workpiece;

6. Modul akwụ ụgwọ nwere ike na-akpaghị aka kwụghachi workpiece n'ọnọdu ma ọ bụ njehie nke fixture na mgbanwe nke workpiece ndidi.

7. Eserese ahụ bụ naanị maka ntụnye aka, nkọwapụta ga-adịkwa n'okpuru nhazi n'ezie.

| Data teknụzụ* | |

| Iwu Mba. | XYR1063 |

| Iji jikọọ flanges dị ka EN ISO 9409-1 | TK 63 |

| Ibu akwadoro [kg]** | 7 |

| Njem axis X/Y +/- (mm) | 3 |

| Ndị agha njide etiti (N] | 300 |

| Ndị agha na-anọghị n'etiti [N] | 100 |

| Nrụgide ikuku kacha arụ ọrụ [bar] | 8 |

| Okpomọkụ arụ ọrụ kacha nta [°C] | 5 |

| Okpomọkụ kachasị arụ ọrụ [°C] | +80 |

| Olu ikuku na-eri kwa okirikiri [cm3] | 6.5 |

| Oge inertia [kg/cm2] | 38.8 |

| Ibu [kg] | 2 |

| * A na-atụ data niile na nrụgide ikuku 6 ** Mgbe agbakọtara na etiti |

Modul akwụ ụgwọ

Modul akwụ ụgwọ nwere ike na-akpaghị aka kwụghachi workpiece n'ọnọdu ma ọ bụ njehie nke fixture na mgbanwe nke workpiece ndidi.

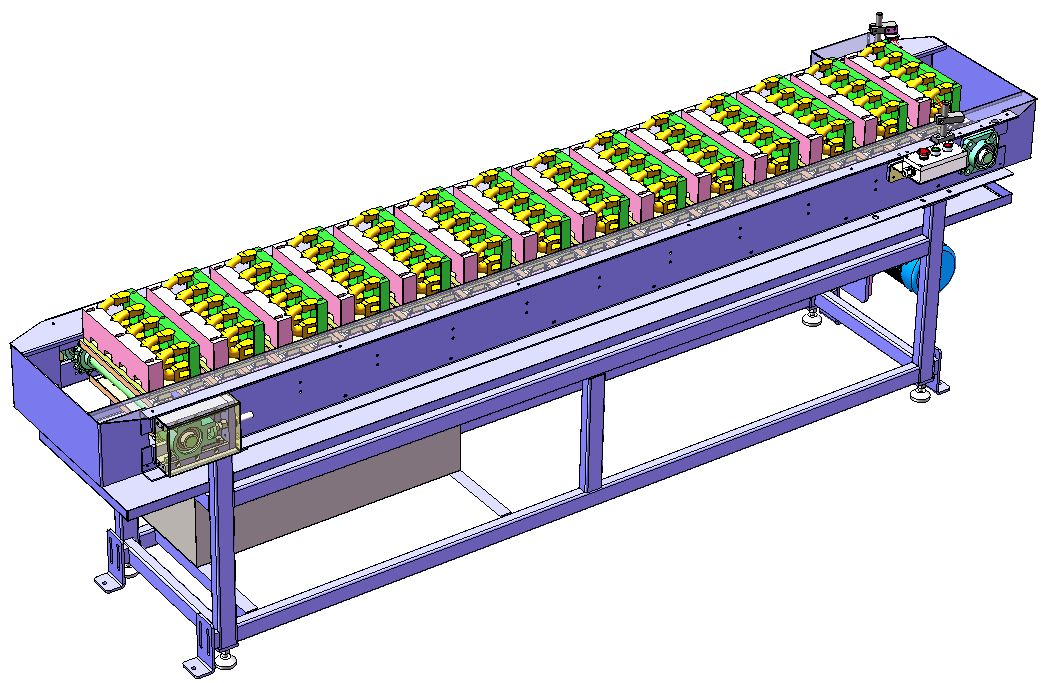

Ahịrị na-ebu na ibufe

1. Loading na ibuga ahịrị adopts yinye otu oyi akwa nnyefe Ọdịdị, na nnukwu nchekwa ikike, mfe ntuziaka ọrụ na elu na-eri arụmọrụ;

2. Ọnụ ọgụgụ a haziri nke a na-etinye ga-ezute ikike mmepụta nke otu awa. N'okpuru ọnọdụ nke nri akwụkwọ ntuziaka mgbe niile n'ime nkeji 60 ọ bụla, enwere ike ịrụ ọrụ na-enweghị mmechi;

3. The ihe tray bụ njehie-àmà, aka akwụkwọ ntuziaka adaba efu, na silo tooling maka workpieces nke dị iche iche nkọwa ga-gbanwee aka;

4. A na-ahọrọ mmanụ na mmiri na-eguzogide ọgwụ, ihe mgbochi na ike dị elu maka nri nri nke silo, na nhazi ntuziaka na-achọrọ mgbe ị na-emepụta ngwaahịa dị iche iche;

5. Eserese a bụ naanị maka ntụnye aka, na nkọwa ga-adị n'okpuru nhazi ahụ n'ezie.

Sistemụ Njikwa Eletriki

1. Gụnyere njikwa usoro na nkwurịta okwu mgbaàmà n'etiti akụrụngwa, gụnyere sensọ, eriri, trunking, switches, wdg;

2. A na-emepụta nkeji akpaka na oriọna mkpuchi agba atọ. N'oge ọrụ nkịtị, oriọna nwere agba atọ na-egosiputa akwụkwọ ndụ akwụkwọ ndụ; ma ọ bụrụ na unit ada ada, atọ-acha oriọna ga-egosipụta red oti mkpu na oge;

3. Enwere bọtịnụ nkwụsị mberede na ụlọ ọrụ nchịkwa na igbe ngosi nke robot. N'ọnọdụ mberede, enwere ike ịpị bọtịnụ nkwụsị mberede iji ghọta usoro nkwụsị mberede mberede ma zipu mgbaama mkpu n'otu oge;

4. Site na onye ngosi, anyị nwere ike ikpokọta ọtụtụ ụdị ngwa ngwa, nke nwere ike izute ihe ndị a chọrọ maka mmeghari ngwaahịa na ịgbakwunye ngwaahịa ọhụrụ;

5. Ihe mgbaàmà nkwụsị mberede niile nke usoro nchịkwa dum na ihe nchebe nchebe n'etiti ngwá ọrụ nhazi na robots na-ejikọta ya na usoro nchekwa ma na-eduzi njikwa na-ejikọta ya site na mmemme njikwa;

6. Usoro nchịkwa na-achọpụta njikọ mgbaàmà n'etiti ngwá ọrụ arụ ọrụ dị ka robots, loading silos, tongs and machine machine machine;

7. Machine ngwá ọrụ usoro kwesịrị ịghọta mgbaama mgbanwe na robot usoro.

Ngwá Ọrụ Nhazi (nke onye ọrụ nyere)

1. Ngwá ọrụ igwe eji eme ihe ga-eji usoro mwepụ nke mgbawa akpaaka (ma ọ bụ iji aka ya na-ehicha ígwè ígwè na mgbe niile) na imeghe ọnụ ụzọ na-emechi ọnụ ụzọ na-akpaghị aka (ma ọ bụrụ na enwere oghere igwe na imechi);

2. N'oge igwe ngwá ọrụ na-arụ ọrụ, ígwè ibe na-adịghị ekwe ka kechie na workpieces, nke nwere ike imetụta clamping na ntinye nke workpieces site robots;

3. N'ịtụle ohere nke mgbawa mgbawa na-adaba n'ụdị ngwá ọrụ igwe, Party B na-agbakwụnye ọrụ ikuku ikuku na tongs robot.

4. Party A ga-ahọrọ ngwaọrụ kwesịrị ekwesị ma ọ bụ teknụzụ mmepụta iji hụ na ndụ ngwá ọrụ ezi uche dị na ya ma ọ bụ na-agbanwe ngwá ọrụ site na onye na-agbanwe ngwá ọrụ n'ime ngwá ọrụ igwe, ka ọ ghara imetụta àgwà nke akpaaka unit n'ihi ngwá ọrụ na-eyi.

5. Nkwukọrịta mgbaàmà n'etiti igwe igwe na robot ga-emejuputa ya site na Party B, na Party A ga-enye akara dị mkpa nke ngwaọrụ igwe dị ka achọrọ.

6. Robot na-eduzi ọnọdụ siri ike mgbe ị na-eburu akụkụ ndị ahụ, na ntinye nke ngwaọrụ igwe na-achọpụta ọnọdụ ziri ezi dị ka ebe ntụaka workpiece si dị.

Nkpuchi nchekwa

1. Tọọ mgbidi nchebe, ọnụ ụzọ nchekwa, mkpuchi nchekwa na ngwaọrụ ndị ọzọ, ma mee ihe nchebe dị mkpa.

2. A ga-edobe ọnụ ụzọ nchekwa n'ọnọdụ kwesịrị ekwesị nke ogige nchekwa. Ọnụ ụzọ niile ga-enwe ngbanwe na bọtịnụ nchekwa, bọtịnụ nrụpụta na bọtịnụ nkwụsị ihe mberede.

3. A na-ejikọta ọnụ ụzọ nchekwa na usoro site na mkpọchi nchekwa (mgbanwe). Mgbe emepere ụzọ nchekwa na-ezighi ezi, sistemụ na-akwụsị wee nye mkpu.

4. Usoro nchekwa nchekwa na-ekwe nkwa nchekwa nke ndị ọrụ na akụrụngwa site na ngwaike na ngwanrọ.

5. The nchekwa nsu nwere ike inye site Party A n'onwe ya. A na-atụ aro iji grid dị elu weld na agba na-acha odo odo na-ekpo ọkụ na-ekpo ọkụ n'elu.

Nkpuchi nchekwa

Mkpọchi nchekwa

Ngwongwo nchekwa gburugburu ebe ọrụ (nke Party A nyere)

| Ịnye ọkụ | Ike ọkọnọ: atọ-adọ anọ-waya AC380V ± 10%, voltaji fluctuation nso ± 10%, ugboro: 50HZ;The ike ọkọnọ nke robot akara kabinet ga-onwem na onwe ikuku mgbanwe; A ga-ejirịrị kabinet na-achịkwa robot gbadaa na nguzogide ala na-erughị 10Ω;Ebe dị irè dị n'etiti isi iyi ọkụ na kabinet njikwa ọkụ eletrik ga-adị n'ime mita 5. |

| Isi iyi ikuku | A ga-ehichapụ ikuku abịakọrọ na mmiri, gas na adịghị ọcha, na nrụgide mmepụta mgbe ọ gafesịrị FRL ga-abụ 0.5 ~ 0.8Mpa; Ebe dị irè dị n'etiti isi iyi ikuku na ahụ robot ga-adị n'ime mita 5. |

| Ntọala | Na-emeso ala ciment nkịtị nke ụlọ ọrụ Party A, na ntọala nrụnye nke akụrụngwa ọ bụla ga-edozi n'ala nke nwere oghere mgbasa; Ike nke ihe eji eme ihe: 210 kg / cm2; Ọkpụrụkpụ nke ihe: Karịrị 150 mm;Ntọala enweghị isi: Ihe na-erughị ± 3mm. |

| Ọnọdụ gburugburu | Ọnọdụ okpomọkụ: 0 ~ 45 ℃; iru mmiri dị ala: 20% ~ 75% RH (anaghị anabata condensation); Ngwa ngwa nke ịma jijiji: Ihe na-erughị 0.5G. |

| Dị iche iche | Zere ikuku na mmiri na-ere ọkụ na nke na-emebi emebi, ma fesa mmanụ, mmiri, uzuzu, wdg; Abịarula ebe ụda eletrik na-esi enweta. |